ABS/PLA? If it's ABS it should be able to be smoothed with acetone (practice with failed prints first!), and you can also smooth by painting/sanding multiple layers until it gets smooth enough.Also, how do you guys sand your 3D parts? I tried going at my trigger with some 200 grit by hand, but it didn't do much. Should I use a tool?

Worklog Ginger's Wii Portable Worklog

- Thread starter GingerOfOz

- Start date

- Joined

- Dec 16, 2016

- Messages

- 1,122

- Likes

- 2,710

- Location

- The Oregon Wildlands

- Portables

- just so many i am so cool

Yeah, I'm using ABS. Would I want to put the acetone on before painting, or after?

- Joined

- Dec 24, 2016

- Messages

- 180

- Likes

- 273

Before.Yeah, I'm using ABS. Would I want to put the acetone on before painting, or after?

Definitely before, acetone is mainly used as paint thinner since it's great at melting things (paint and plastic are two examples). I would also suggest using it in a well ventilated area, or better yet, outside.

It'd be nice if the listings said if they're high or low signal >.>SDN--->5v to turn on

- Joined

- Feb 25, 2016

- Messages

- 1,437

- Likes

- 2,887

"SDN switch pin, high power, low shutdown,can single-chip control"It'd be nice if the listings said if they're high or low signal >.>

smh..

http://www.ebay.com/itm/181406329936?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

Second time I've done this in two days. WELP, these pills are bad. I'm just gonna... go >.>"SDN switch pin, high power, low shutdown,can single-chip control"

smh..

http://www.ebay.com/itm/181406329936?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

Second time I've done this in two days. WELP, these pills are bad. I'm just gonna... go >.>

- Joined

- Dec 16, 2016

- Messages

- 1,122

- Likes

- 2,710

- Location

- The Oregon Wildlands

- Portables

- just so many i am so cool

Are you saying you have to wire 5v to the +5v pin then wire the +5v pin to the SDN pin for it to work?SDN--->5v to turn on

- Joined

- Mar 3, 2016

- Messages

- 2,229

- Likes

- 2,952

- Portables

- 2

Yes. That's the shutdown pin that must be connected to 5V for the amplifier to workAre you saying you have to wire 5v to the +5v pin then wire the +5v pin to the SDN pin for it to work?

- Joined

- Feb 13, 2017

- Messages

- 243

- Likes

- 47

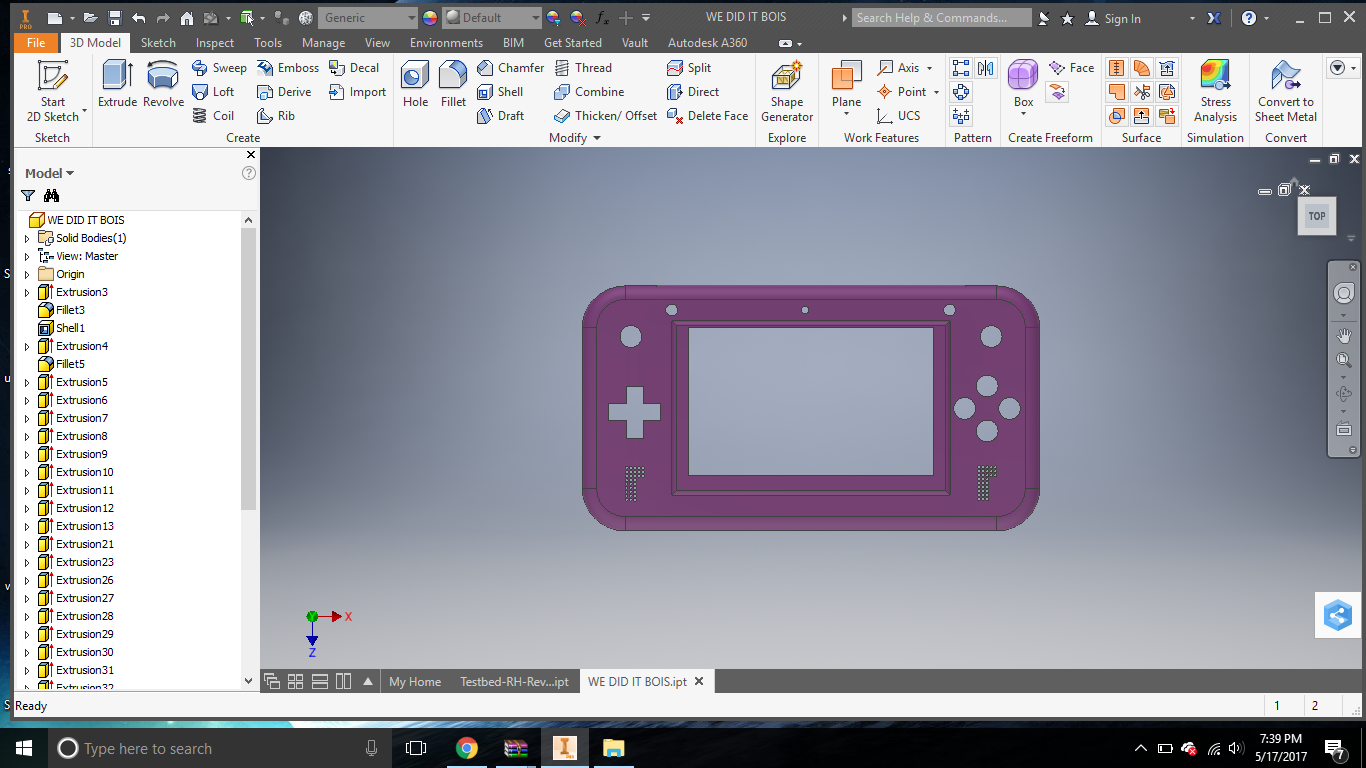

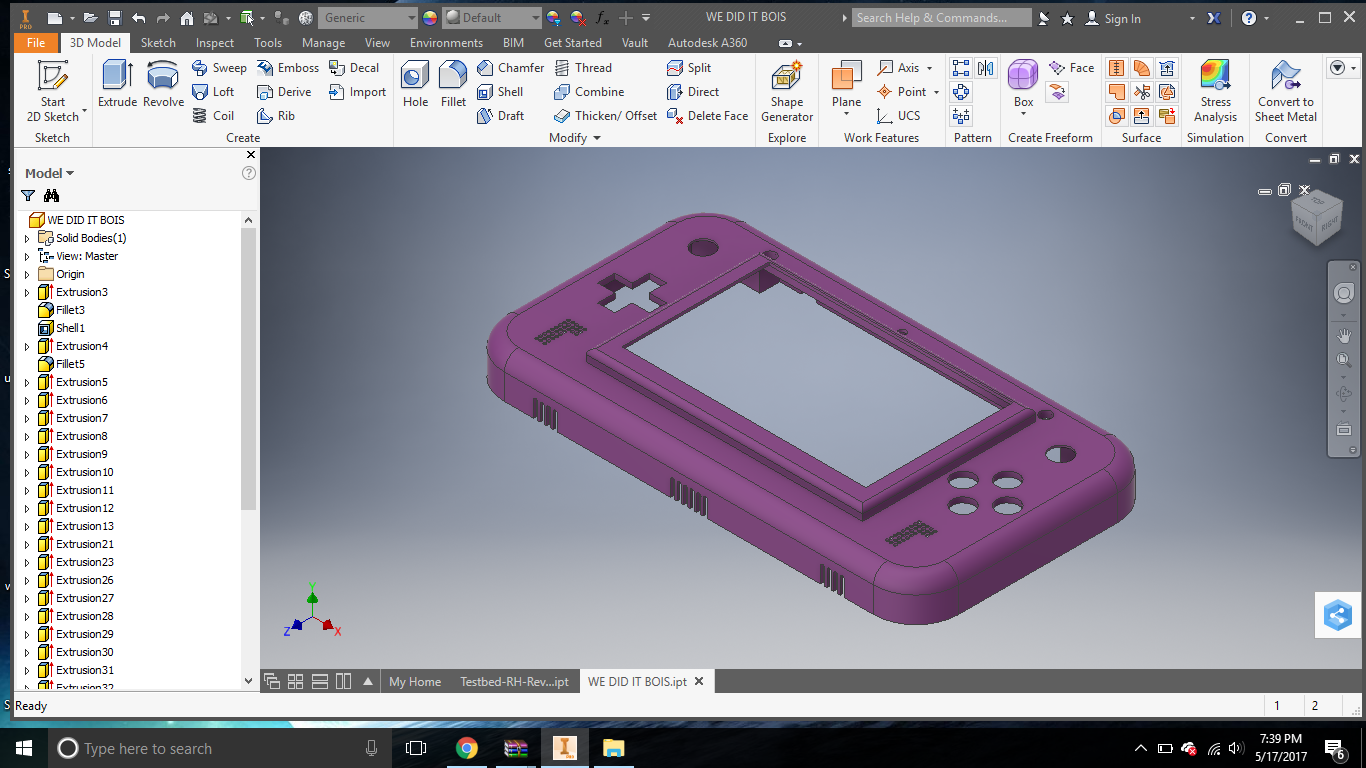

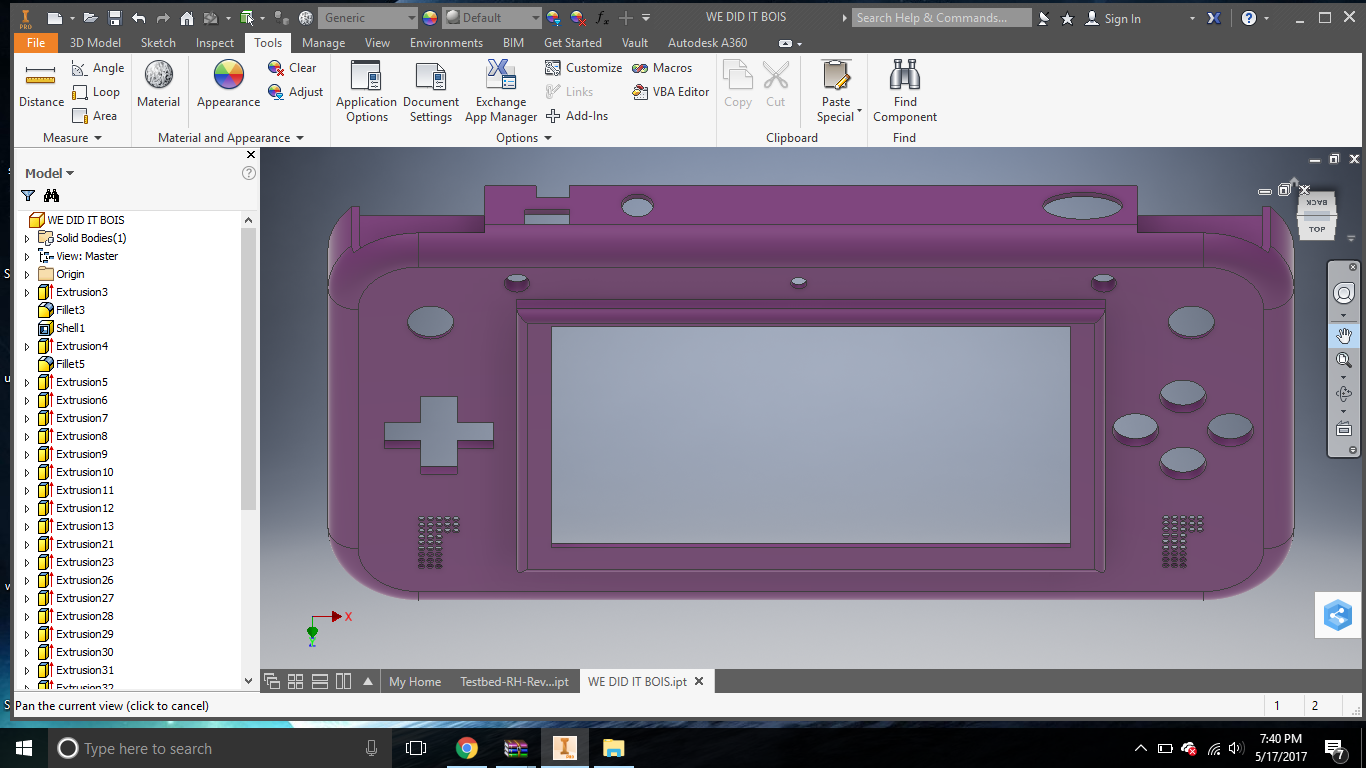

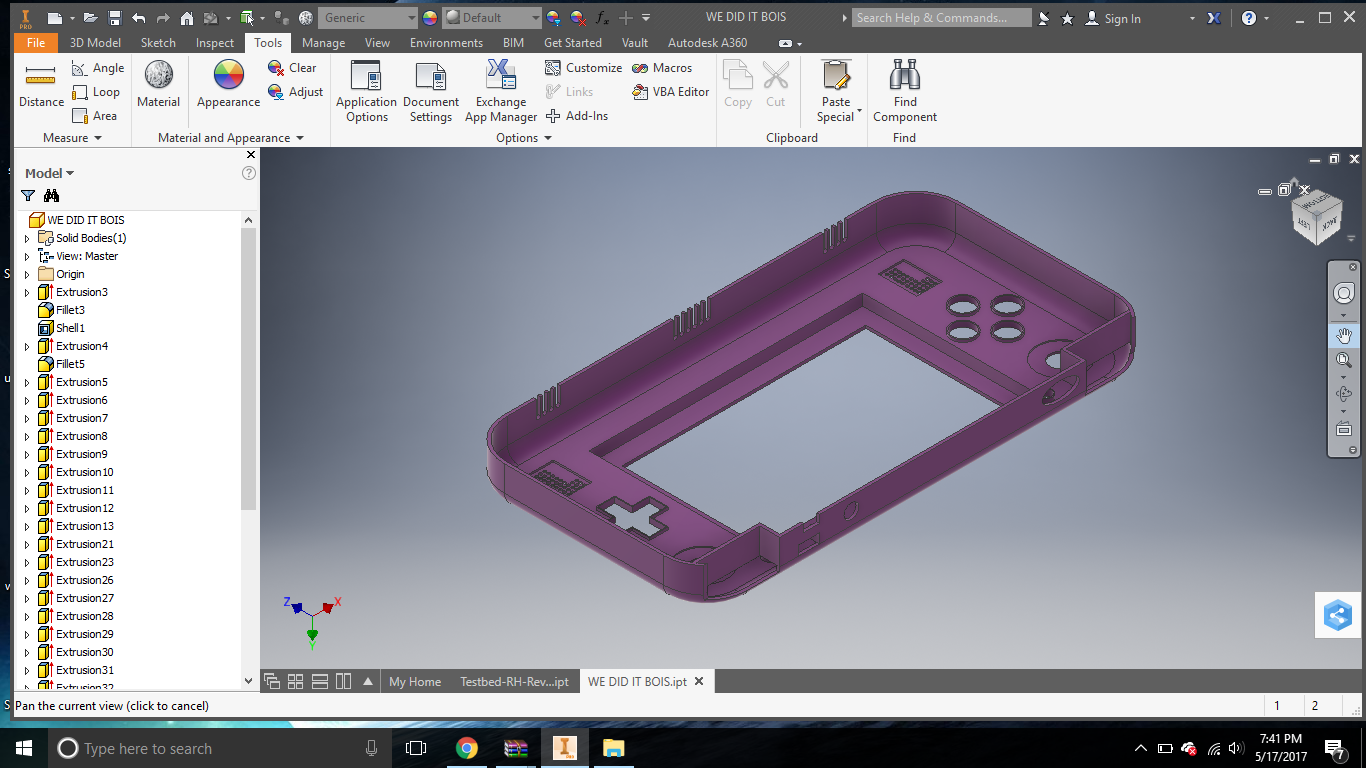

I was just wondering what program you're using to 3D print your case?Spicy case pics:View attachment 2291 View attachment 2292 View attachment 2293 The next step will be adding the slots in the top for USB/ Switches/ LRZ, as well as holes for ABXY, Dpad, and my IR LEDs. It goes slowly, but it should be beautiful once it's finished...

- Joined

- Dec 16, 2016

- Messages

- 1,122

- Likes

- 2,710

- Location

- The Oregon Wildlands

- Portables

- just so many i am so cool

Autodesk Inventor 2017. It's pretty awesome, but can be difficult to learn. It's also free if you're a student.I was just wondering what program you're using to 3D print your case?

- Joined

- Feb 13, 2017

- Messages

- 243

- Likes

- 47

Ohhhhh I'll look into that, seems pretty interestingAutodesk Inventor 2017. It's pretty awesome, but can be difficult to learn. It's also free if you're a student.

- Joined

- Dec 16, 2016

- Messages

- 1,122

- Likes

- 2,710

- Location

- The Oregon Wildlands

- Portables

- just so many i am so cool

Wrapped up (hopefully) the front/mid section of my case.

I'm just about ready to e-mail the part to my teacher to get it printed out. Before I do that, I'm going to take @Shank 's advice and print the screen part separately so that the rest of the body has a nice flat surface to print on. I'm not too worried about the other things that don't have a solid foundation because the good 3D printer prints structural material to help the part from correctly. You have to put the part into an acid bath for 24 hours, but it comes out looking really nice. I'm also going to add some screw posts for me to screw into before I send it off.

I plan to have more ventilation than what is on the bottom of the case. That there is just extra, because I figure it's better to have too much airflow than too little.

In other news, I got my IR LEDs working, so my sensor bar works too! The two widely spaced holes near the top of the case are for those. The little one in the middle is a little white LED I'm using as my rumble. I was considering putting in a switch to turn the sensor bar on/off, but I don't feel like the LEDs would really drain that much juice. I've also decided to drop the headphone jack, because it looks like that process is currently more complicated than I had anticipated. (At least until @Aurelio finishes the amp he's cooking up...)

If you have any last minute suggestions/critiques on the case please let me know!

I'm just about ready to e-mail the part to my teacher to get it printed out. Before I do that, I'm going to take @Shank 's advice and print the screen part separately so that the rest of the body has a nice flat surface to print on. I'm not too worried about the other things that don't have a solid foundation because the good 3D printer prints structural material to help the part from correctly. You have to put the part into an acid bath for 24 hours, but it comes out looking really nice. I'm also going to add some screw posts for me to screw into before I send it off.

I plan to have more ventilation than what is on the bottom of the case. That there is just extra, because I figure it's better to have too much airflow than too little.

In other news, I got my IR LEDs working, so my sensor bar works too! The two widely spaced holes near the top of the case are for those. The little one in the middle is a little white LED I'm using as my rumble. I was considering putting in a switch to turn the sensor bar on/off, but I don't feel like the LEDs would really drain that much juice. I've also decided to drop the headphone jack, because it looks like that process is currently more complicated than I had anticipated. (At least until @Aurelio finishes the amp he's cooking up...)

If you have any last minute suggestions/critiques on the case please let me know!

- Joined

- Feb 13, 2017

- Messages

- 243

- Likes

- 47

Cool, is the official color purple?Wrapped up (hopefully) the front/mid section of my case.

View attachment 2501 View attachment 2504 View attachment 2502 View attachment 2503

I'm just about ready to e-mail the part to my teacher to get it printed out. Before I do that, I'm going to take @Shank 's advice and print the screen part separately so that the rest of the body has a nice flat surface to print on. I'm not too worried about the other things that don't have a solid foundation because the good 3D printer prints structural material to help the part from correctly. You have to put the part into an acid bath for 24 hours, but it comes out looking really nice. I'm also going to add some screw posts for me to screw into before I send it off.

I plan to have more ventilation than what is on the bottom of the case. That there is just extra, because I figure it's better to have too much airflow than too little.

In other news, I got my IR LEDs working, so my sensor bar works too! The two widely spaced holes near the top of the case are for those. The little one in the middle is a little white LED I'm using as my rumble. I was considering putting in a switch to turn the sensor bar on/off, but I don't feel like the LEDs would really drain that much juice. I've also decided to drop the headphone jack, because it looks like that process is currently more complicated than I had anticipated. (At least until @Aurelio finishes the amp he's cooking up...)

If you have any last minute suggestions/critiques on the case please let me know!

I see what you did with the speaker holes ;3Wrapped up (hopefully) the front/mid section of my case.

View attachment 2501 View attachment 2504 View attachment 2502 View attachment 2503

I'm just about ready to e-mail the part to my teacher to get it printed out. Before I do that, I'm going to take @Shank 's advice and print the screen part separately so that the rest of the body has a nice flat surface to print on. I'm not too worried about the other things that don't have a solid foundation because the good 3D printer prints structural material to help the part from correctly. You have to put the part into an acid bath for 24 hours, but it comes out looking really nice. I'm also going to add some screw posts for me to screw into before I send it off.

I plan to have more ventilation than what is on the bottom of the case. That there is just extra, because I figure it's better to have too much airflow than too little.

In other news, I got my IR LEDs working, so my sensor bar works too! The two widely spaced holes near the top of the case are for those. The little one in the middle is a little white LED I'm using as my rumble. I was considering putting in a switch to turn the sensor bar on/off, but I don't feel like the LEDs would really drain that much juice. I've also decided to drop the headphone jack, because it looks like that process is currently more complicated than I had anticipated. (At least until @Aurelio finishes the amp he's cooking up...)

If you have any last minute suggestions/critiques on the case please let me know!

- Joined

- Dec 16, 2016

- Messages

- 1,122

- Likes

- 2,710

- Location

- The Oregon Wildlands

- Portables

- just so many i am so cool

Cool, is the official color purple?

Ohhhhhhhh, yeeaaaahhhhhhhdibs on the name WaluWiigi!!!!

- Joined

- Jan 31, 2016

- Messages

- 1,287

- Likes

- 2,726

- Portables

- 6

Is it a uprint? If so, you may not need to print the bezel as a separate piece. The dissolvable fatty support material makes supported areas come out clean, unlike single material printers. I have access to uprints, but I avoid them because the plastic is proprietary and expensive (like a dollar a gram), and you have to buy a new print bed every time you print something.