- Joined

- Jan 15, 2021

- Messages

- 49

- Likes

- 112

- Location

- Not quite socialist North Europe

- Portables

- GB Adwiince v2

So I have officially abandoned my first project after having my display driver board blow up on me, and failing to do the nand relocation.

So I'm starting a new project/iteration to join the summer contest.

My goal is to frankencase two translucent GameBoy Advance shells to fit a 5" component display and the cut-down Wii.

So I'll be using the RVL PMS and the USB C PD charger and internal USB combo for power, along with hopefully two 18650 batteries if I can fit them, along with the GC+ v2 for controls and 64amp using analogue input for audio. (The U-Amp was out of stock when I ordered, and I didn't dare to wait any longer in case the other components went out of stock too.)

So I'll be using the RVL PMS and the USB C PD charger and internal USB combo for power, along with hopefully two 18650 batteries if I can fit them, along with the GC+ v2 for controls and 64amp using analogue input for audio. (The U-Amp was out of stock when I ordered, and I didn't dare to wait any longer in case the other components went out of stock too.)

I plan to include the MX chip and try to add the Bluetooth module, though they are rather optional for me.

My original plan was for an LMAO cut, as I needed to slim down the board to fit the batteries on either side of the board, but after tragically failing to use the flex pcbs and ruining them, I'll ditch that thought for now, and just do an OMG cut, and look at what I can do for the batteries later.

I plan to reuse the buttons and d-pad for the GBA shell, but the original holes for them are annoyingly high, so the joysticks will have to be below them, which I don't like, I'm looking into if I should cut out the original holes and move them down enough to fit the joysticks above the buttons. Also, I don't have much speaker room, so they will probably be downwards firing, placed in the lowest bumps under the screen (I selected ones slim enough to specifically fit in that space in case there were nowhere else to put them.)

I also plan to use several 3.5mm trrc jacks to give me component video out, and Gamecube controller out, along with the standard audio out. In the original idea, I had planned to use the GBA Gamecube adapter to add those ports, but the screen will be in the way of where that port would normally be, so that will probably be scrapped, I also had plans for adding a jack to support the sensor bar, but I'll probably scrap that as you can get battery-powered sensor bars anyway.

I also plan to use several 3.5mm trrc jacks to give me component video out, and Gamecube controller out, along with the standard audio out. In the original idea, I had planned to use the GBA Gamecube adapter to add those ports, but the screen will be in the way of where that port would normally be, so that will probably be scrapped, I also had plans for adding a jack to support the sensor bar, but I'll probably scrap that as you can get battery-powered sensor bars anyway.

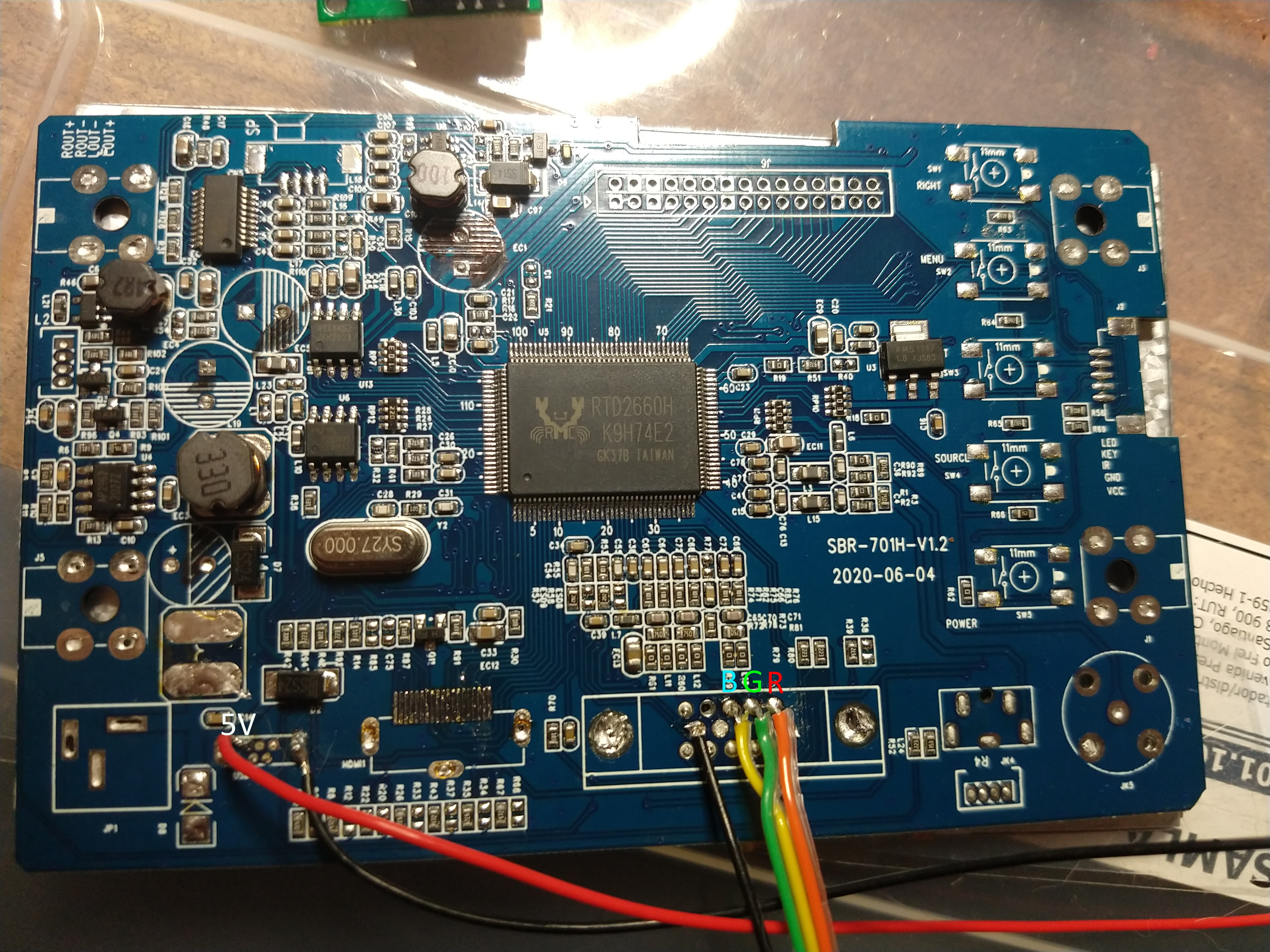

I started working on this iteration of the project this week, after getting over my anxiety from my previous failed projects. So for what I have done so far, I have soldered the PMS to the PD so that I could test the display, and I have stripped the display board of all the posts and ports. As my previous driver board exploded when I heated up a capacitor too much, I ended up removing all the capacitors first with my soldering iron. I had planned to add them one by one to see which ones were needed, and which ones were only supporting the 12v to 5v stepdown. But to my surprise, the board runs fine without any capacitors, and I have not noticed any signal issues or degradation with or without them, sooo as the capacitors are tall and placed in an inconvenient spot where I had planned to station one of my batteries, I'll just run without any capacitors for now.

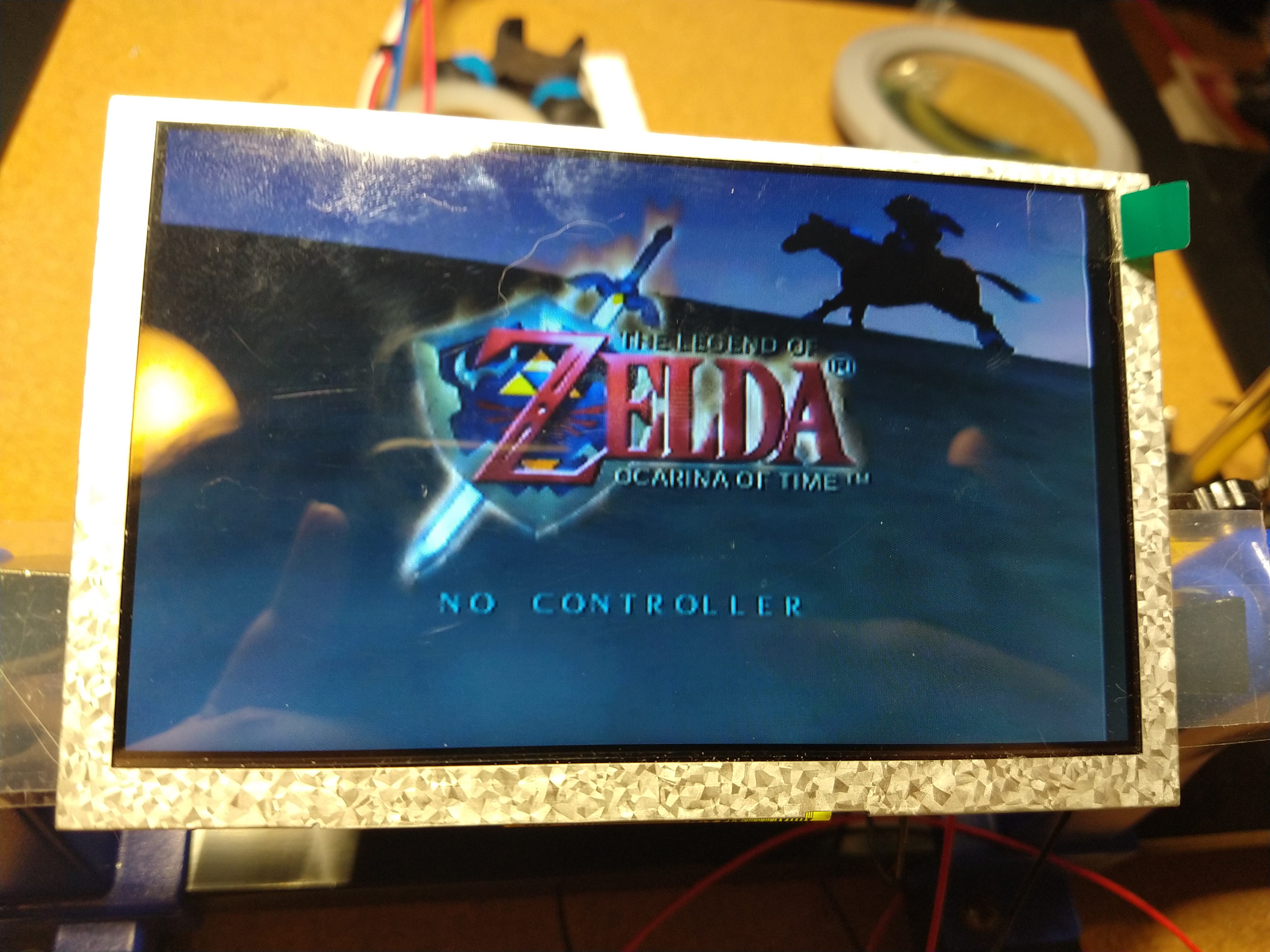

Used my RGB modded N64 to test the input, as it is quick to start right into the title screen, where I can test the colors and quality quickly.

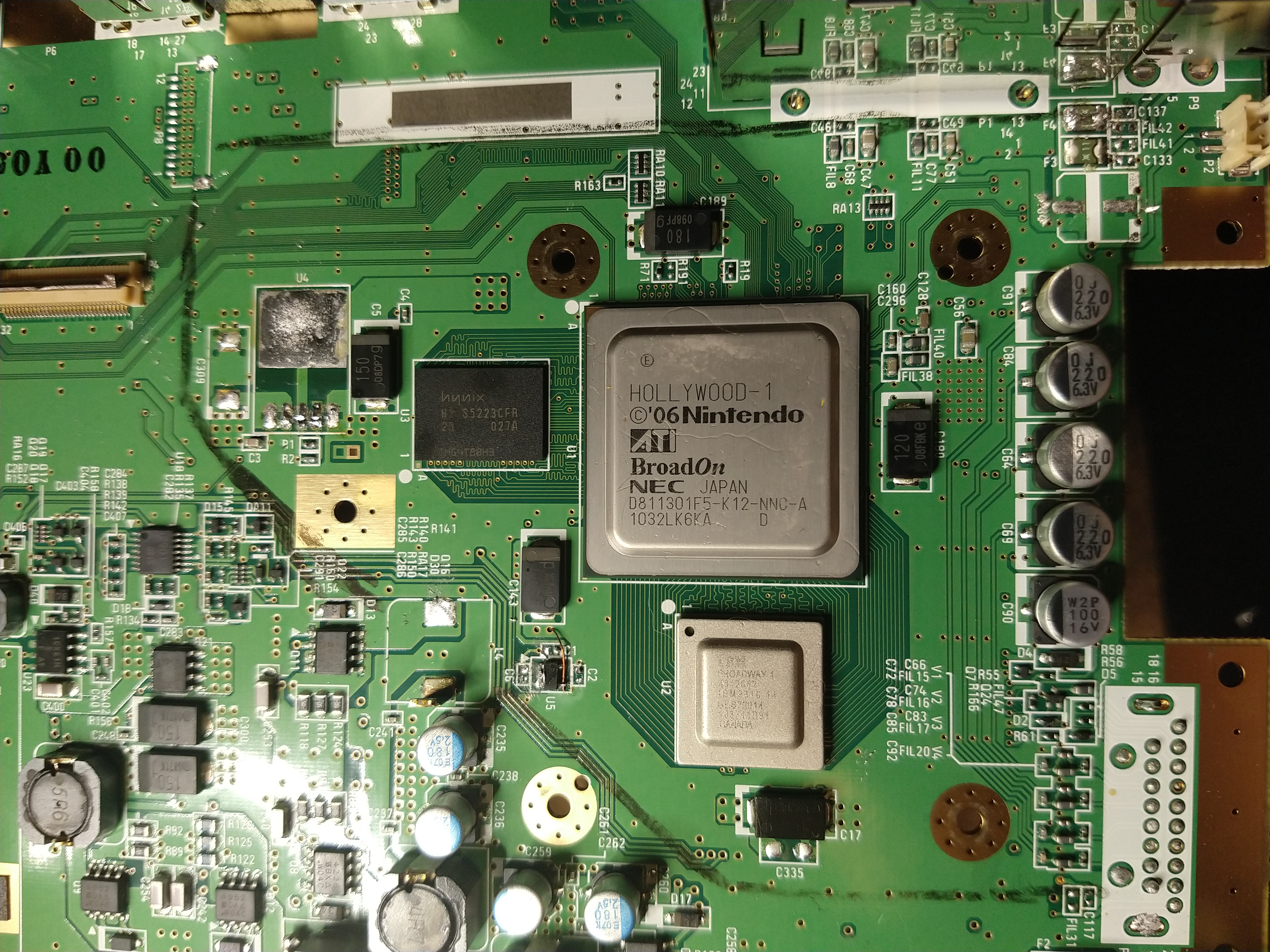

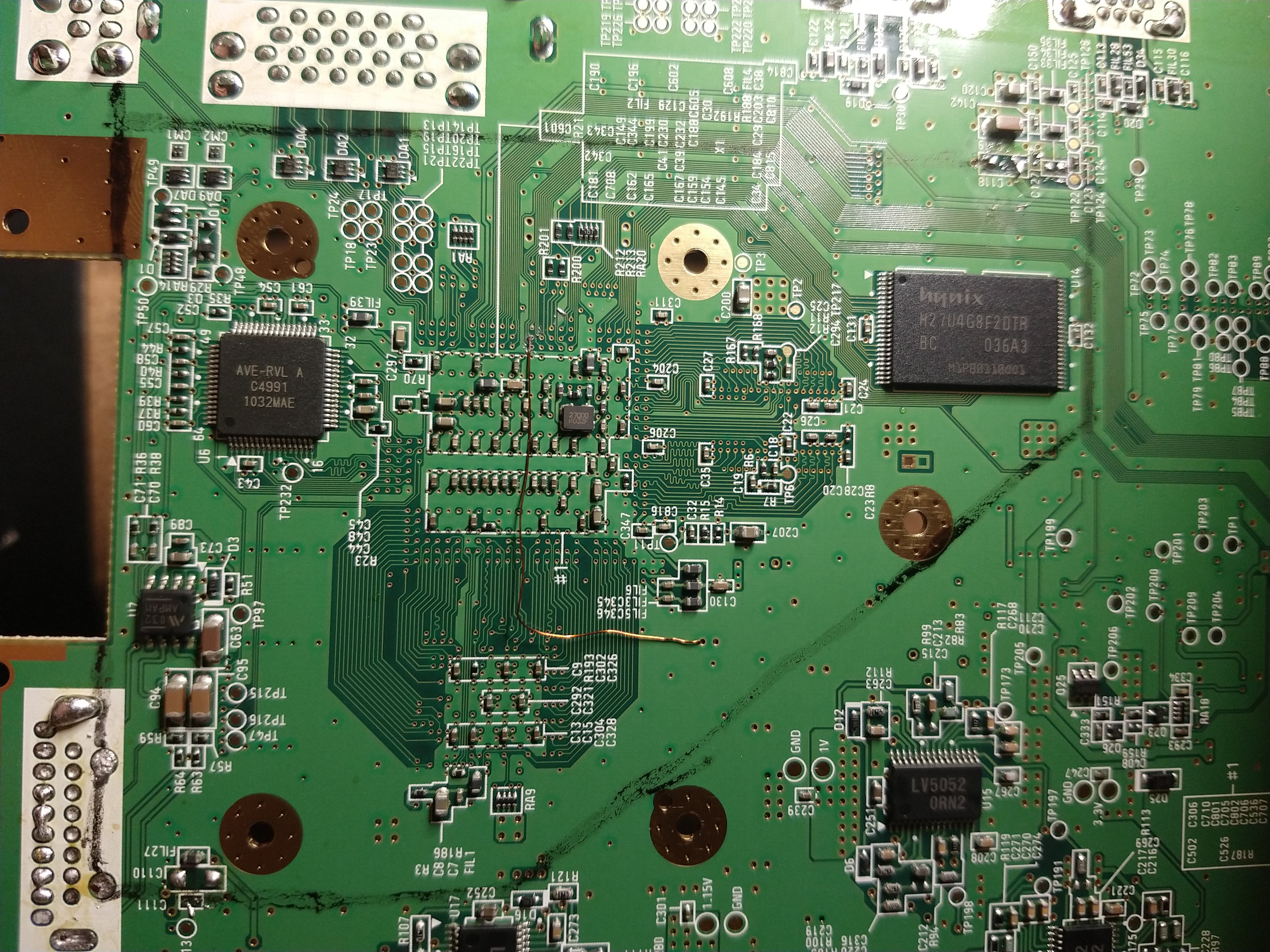

And with the display stripped down I moved on to moving the U10 chip and removing all the components that would be in the way of cutting the board down. I plan to cut from the underside starting outside the lines and sanding inwards. Ignore the lines on the top side, I drew those first to see the footprint for if it would fit in the case.

And with the display stripped down I moved on to moving the U10 chip and removing all the components that would be in the way of cutting the board down. I plan to cut from the underside starting outside the lines and sanding inwards. Ignore the lines on the top side, I drew those first to see the footprint for if it would fit in the case.

(I'll go over all the components I removed to ensure they did not get bridge when I removed them, the LDO pins seem a bit to close from this angle)

I'll probably do the cutting tomorrow, I glued the battery doors on the GBA shells to the shells themselves so that they will be properly attached and I can cut away the interior that is holding them in place normally, so I'll have to wait for the plastic glue to fully set.

I'll probably do the cutting tomorrow, I glued the battery doors on the GBA shells to the shells themselves so that they will be properly attached and I can cut away the interior that is holding them in place normally, so I'll have to wait for the plastic glue to fully set.

(And just to document for those who were curious about my failed nand relocation, what happened was that my heat gun blows a bit too forcefully, so it made the components I'm trying to place down constantly move out of place, (I realized later that I could have added weight to the nand to make it stand still but it was already too late,) so I decided to try to single pin solder the nand to the flex, but I think I ran the iron to hot and scorched the flex so that solder no longer wanted to stick to it, I tried electronics cleaner and flux pen to no avail. And the iron tip was a bit too big so that it would bridge the pins on the nand and cleaning up the solder make it even worse. I was close one time to make it work, all the pins on the flex were on properly and all the data pins were connected to the Wii, but I was struggling with the ground pins and the 3.3v as I had not pre-tinned them, as I hadn't realized that those vias were supposed to be connected too, intill all the other ones were set, so I ended up desoldering the flex to get better access, which caused some of the nand pins to lose grip, and I couldn't make them stick again. I should just have added two wires manually for ground and 3.3v and I would have had a LMAO ready Wii, but it is too late for that now. Live and learn, I guess. Anyway, now that the store is down, I can't get a new flex to try again. Unless I try for the LMAOv1 with only desoldering one side of the nand and bending it over, and adding the final 10 wires manually, though with a finer tipped iron than my current one. I did try to add all the wires manually as a last hail mary on my failed nand relocation board, but my iron was again too large, desoldering the wires I had already added whenever I tried to add a new wire. I think I can do it with some more patience and the finer iron tip I plan to order. Though I would have to try on a different board, as my cat stole the nand when I left the room, and I can't find it anymore.)

Edit: (19/09/2021) Moved images into spoilers to improve load times hopefully

So I'm starting a new project/iteration to join the summer contest.

My goal is to frankencase two translucent GameBoy Advance shells to fit a 5" component display and the cut-down Wii.

I plan to include the MX chip and try to add the Bluetooth module, though they are rather optional for me.

My original plan was for an LMAO cut, as I needed to slim down the board to fit the batteries on either side of the board, but after tragically failing to use the flex pcbs and ruining them, I'll ditch that thought for now, and just do an OMG cut, and look at what I can do for the batteries later.

I plan to reuse the buttons and d-pad for the GBA shell, but the original holes for them are annoyingly high, so the joysticks will have to be below them, which I don't like, I'm looking into if I should cut out the original holes and move them down enough to fit the joysticks above the buttons. Also, I don't have much speaker room, so they will probably be downwards firing, placed in the lowest bumps under the screen (I selected ones slim enough to specifically fit in that space in case there were nowhere else to put them.)

I started working on this iteration of the project this week, after getting over my anxiety from my previous failed projects. So for what I have done so far, I have soldered the PMS to the PD so that I could test the display, and I have stripped the display board of all the posts and ports. As my previous driver board exploded when I heated up a capacitor too much, I ended up removing all the capacitors first with my soldering iron. I had planned to add them one by one to see which ones were needed, and which ones were only supporting the 12v to 5v stepdown. But to my surprise, the board runs fine without any capacitors, and I have not noticed any signal issues or degradation with or without them, sooo as the capacitors are tall and placed in an inconvenient spot where I had planned to station one of my batteries, I'll just run without any capacitors for now.

Used my RGB modded N64 to test the input, as it is quick to start right into the title screen, where I can test the colors and quality quickly.

(I'll go over all the components I removed to ensure they did not get bridge when I removed them, the LDO pins seem a bit to close from this angle)

(And just to document for those who were curious about my failed nand relocation, what happened was that my heat gun blows a bit too forcefully, so it made the components I'm trying to place down constantly move out of place, (I realized later that I could have added weight to the nand to make it stand still but it was already too late,) so I decided to try to single pin solder the nand to the flex, but I think I ran the iron to hot and scorched the flex so that solder no longer wanted to stick to it, I tried electronics cleaner and flux pen to no avail. And the iron tip was a bit too big so that it would bridge the pins on the nand and cleaning up the solder make it even worse. I was close one time to make it work, all the pins on the flex were on properly and all the data pins were connected to the Wii, but I was struggling with the ground pins and the 3.3v as I had not pre-tinned them, as I hadn't realized that those vias were supposed to be connected too, intill all the other ones were set, so I ended up desoldering the flex to get better access, which caused some of the nand pins to lose grip, and I couldn't make them stick again. I should just have added two wires manually for ground and 3.3v and I would have had a LMAO ready Wii, but it is too late for that now. Live and learn, I guess. Anyway, now that the store is down, I can't get a new flex to try again. Unless I try for the LMAOv1 with only desoldering one side of the nand and bending it over, and adding the final 10 wires manually, though with a finer tipped iron than my current one. I did try to add all the wires manually as a last hail mary on my failed nand relocation board, but my iron was again too large, desoldering the wires I had already added whenever I tried to add a new wire. I think I can do it with some more patience and the finer iron tip I plan to order. Though I would have to try on a different board, as my cat stole the nand when I left the room, and I can't find it anymore.)

Edit: (19/09/2021) Moved images into spoilers to improve load times hopefully

Last edited:

keep it uuuup

keep it uuuup