Hello all! I'm super excited to finally start working on a portable Wii!  I got inspired 2 years ago after watching LTT's video on the G-Boy. Now that I finally have a disposable income and an unsuspecting Wii, I can start on this project! Unfortunately, after rediscovering the G-Boy Kits and learning about their lack of stock, I was saddened. Luckily not all was lost. I learned about 4LayerTech, the amazing build guides from the likes of Ginger/Shank/Gman, and the modifications @Dustin Fisher made to the original PCBs and STLs. I now have a path forward to bring a G-Boy to life!

I got inspired 2 years ago after watching LTT's video on the G-Boy. Now that I finally have a disposable income and an unsuspecting Wii, I can start on this project! Unfortunately, after rediscovering the G-Boy Kits and learning about their lack of stock, I was saddened. Luckily not all was lost. I learned about 4LayerTech, the amazing build guides from the likes of Ginger/Shank/Gman, and the modifications @Dustin Fisher made to the original PCBs and STLs. I now have a path forward to bring a G-Boy to life!

With all the resources available, it feels like a scavenger hunt to find out everything that's needed. I think I have enough to get started so I pulled the trigger on the first batch of parts yesterday. I'll be collecting the parts and links into a BOM that I'll link in this thread. Along with this, I hope to scribe helpful hints (and struggles) such that people can learn from my actions as the build progresses.

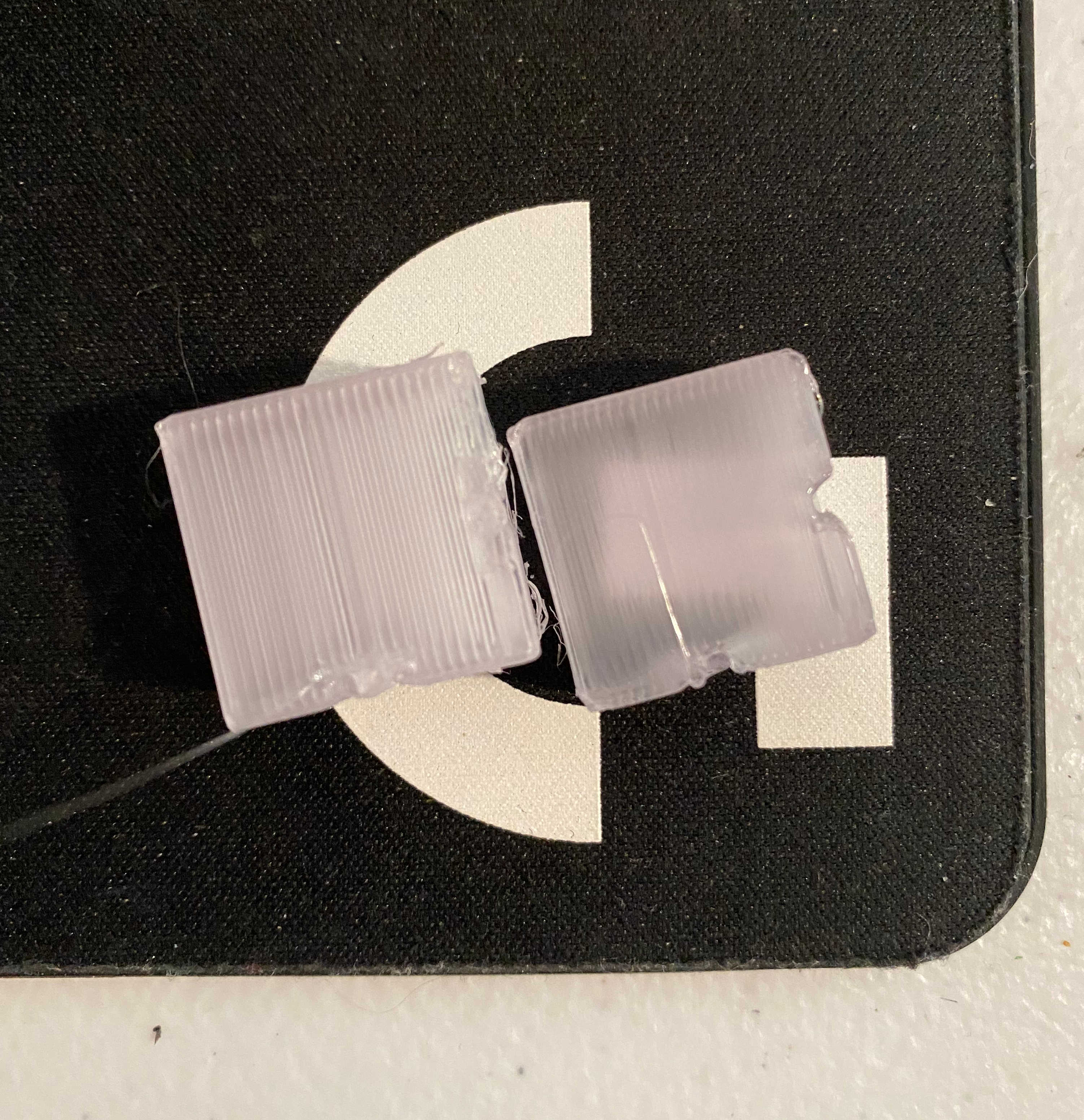

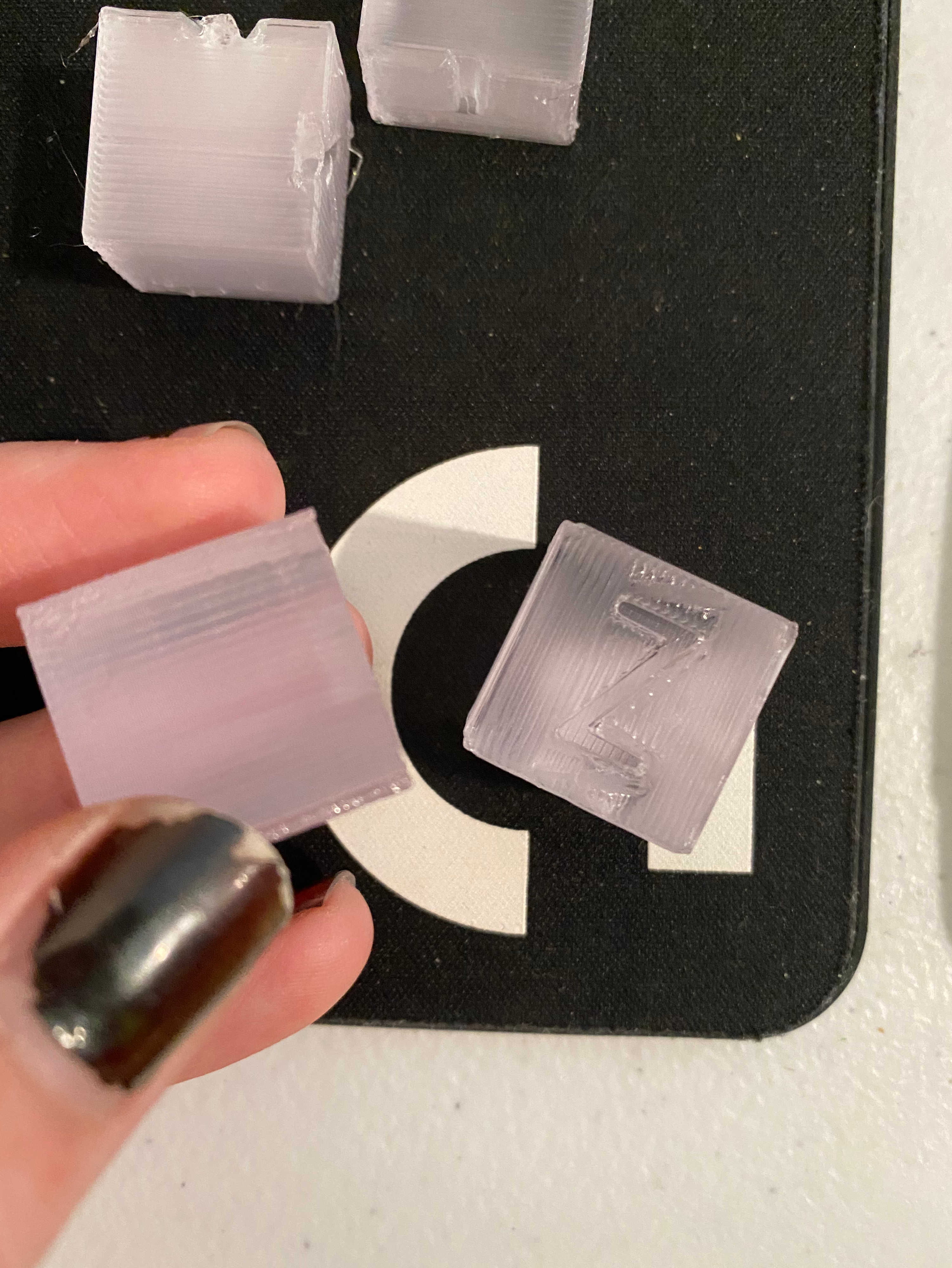

While waiting for parts to arrive, I figured I can start work on the most important part... the case! I wanted my build to be transparent with as much of the shell to be 3D printed as possible. I used advice from CNC Kitchen on Youtube to tune my printer for transparent PETG filament. Bellow are some of my initial tests on reducing the cloudiness of the prints. Pretty happy with the results after lots of tweaking. If people are interested I can post the exact settings used.

The basic idea is to print at a lower heat, slower speed, no top/bottom layers, single wall width, >100% infill flow rate (to fill out voids inside the part), and 100% infill amount. These settings have the added benefit of increasing the strength of 3D printed parts.

The basic idea is to print at a lower heat, slower speed, no top/bottom layers, single wall width, >100% infill flow rate (to fill out voids inside the part), and 100% infill amount. These settings have the added benefit of increasing the strength of 3D printed parts.

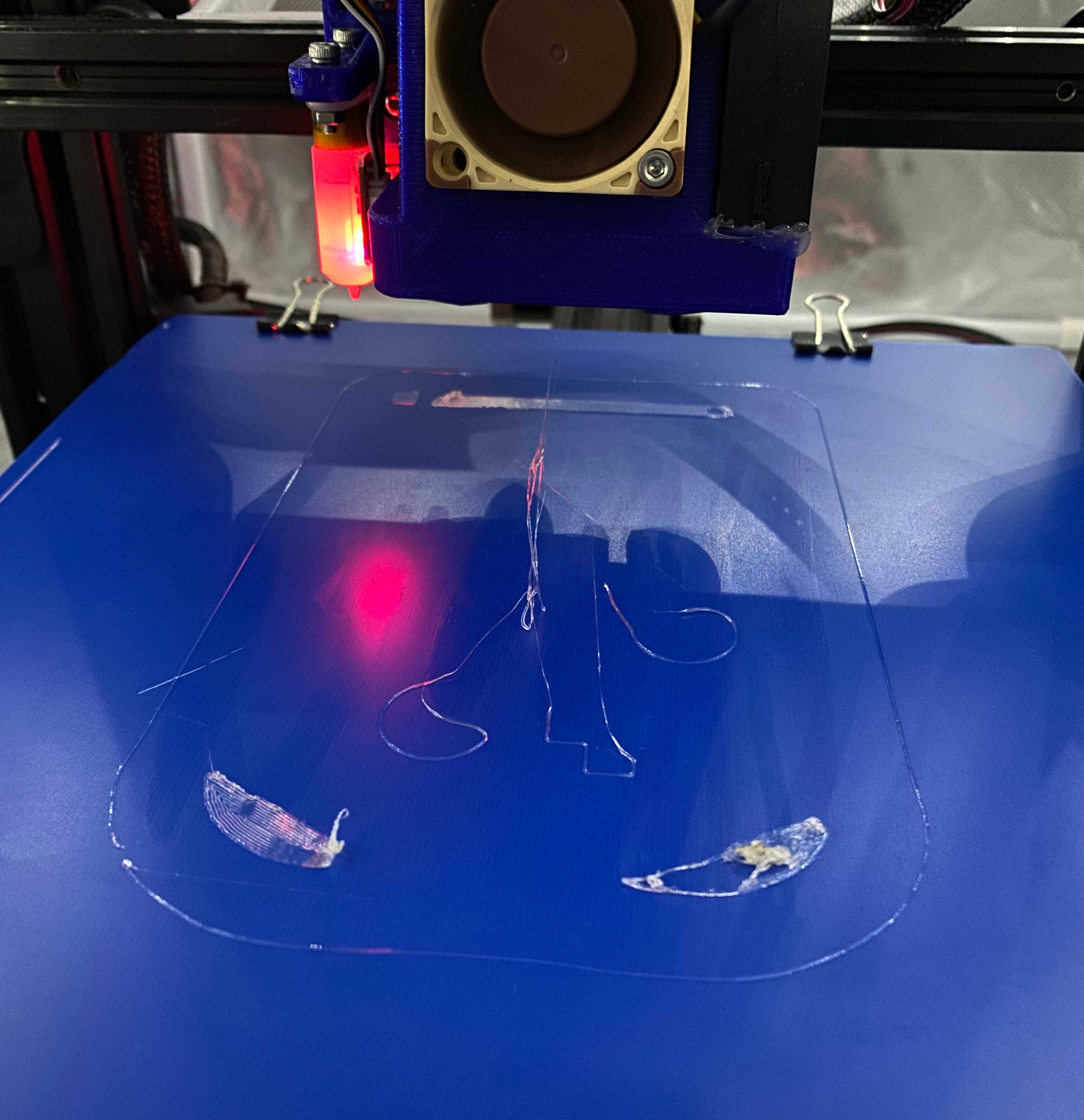

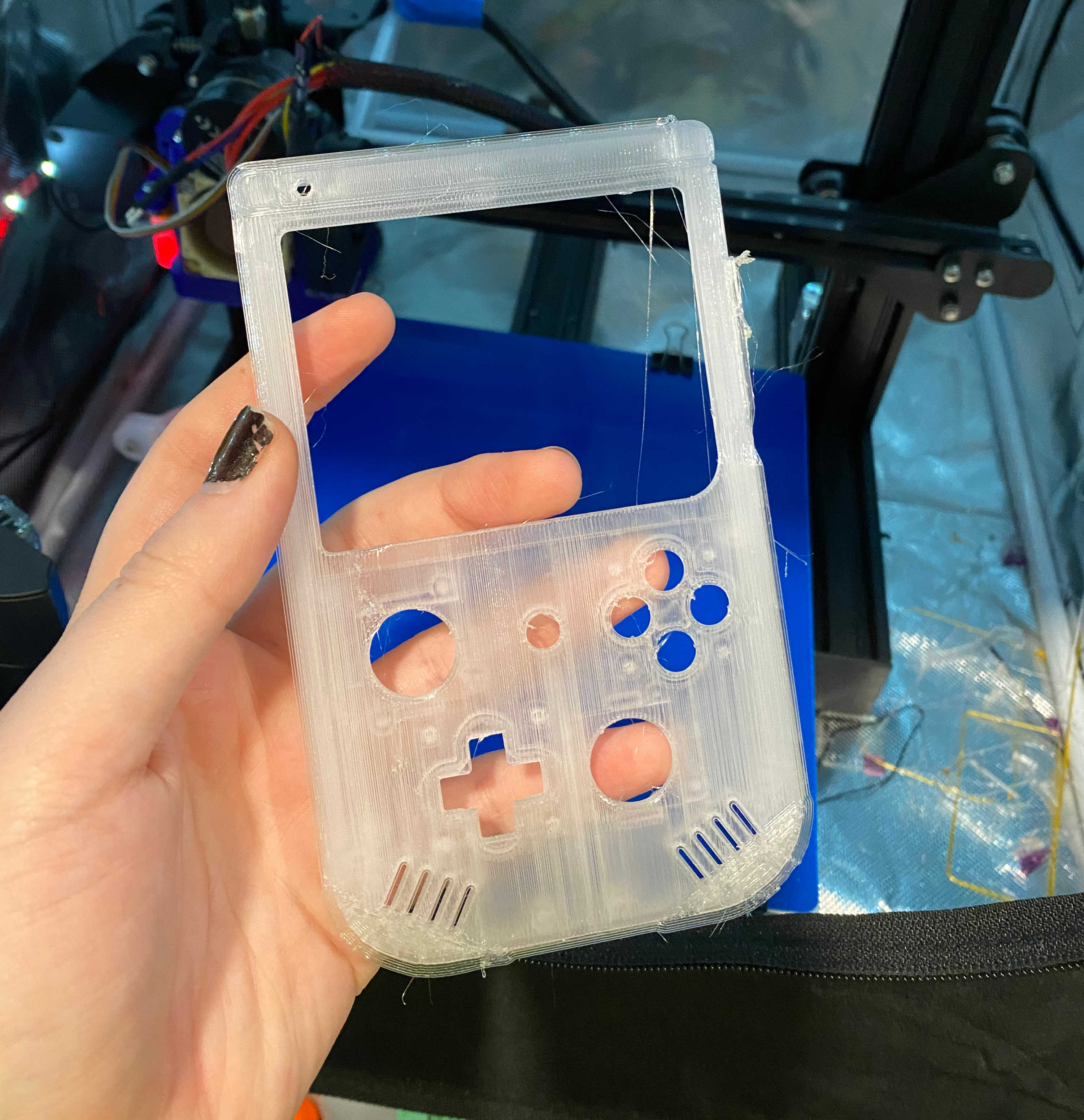

After some struggle on build plate adhesion, I got a first case half printed!

Here's an example of what a PCB would look like shining through the case using a spare one I had laying around:

Here's an example of what a PCB would look like shining through the case using a spare one I had laying around:

More posts to follow! Thanks for reading!

I got inspired 2 years ago after watching LTT's video on the G-Boy. Now that I finally have a disposable income and an unsuspecting Wii, I can start on this project! Unfortunately, after rediscovering the G-Boy Kits and learning about their lack of stock, I was saddened. Luckily not all was lost. I learned about 4LayerTech, the amazing build guides from the likes of Ginger/Shank/Gman, and the modifications @Dustin Fisher made to the original PCBs and STLs. I now have a path forward to bring a G-Boy to life!

I got inspired 2 years ago after watching LTT's video on the G-Boy. Now that I finally have a disposable income and an unsuspecting Wii, I can start on this project! Unfortunately, after rediscovering the G-Boy Kits and learning about their lack of stock, I was saddened. Luckily not all was lost. I learned about 4LayerTech, the amazing build guides from the likes of Ginger/Shank/Gman, and the modifications @Dustin Fisher made to the original PCBs and STLs. I now have a path forward to bring a G-Boy to life!With all the resources available, it feels like a scavenger hunt to find out everything that's needed. I think I have enough to get started so I pulled the trigger on the first batch of parts yesterday. I'll be collecting the parts and links into a BOM that I'll link in this thread. Along with this, I hope to scribe helpful hints (and struggles) such that people can learn from my actions as the build progresses.

While waiting for parts to arrive, I figured I can start work on the most important part... the case! I wanted my build to be transparent with as much of the shell to be 3D printed as possible. I used advice from CNC Kitchen on Youtube to tune my printer for transparent PETG filament. Bellow are some of my initial tests on reducing the cloudiness of the prints. Pretty happy with the results after lots of tweaking. If people are interested I can post the exact settings used.

After some struggle on build plate adhesion, I got a first case half printed!

I'm interested in your ENIG finished boards! I live in the US so we can sort that out in a DM. I'm assuming it's the gold plating that makes the difference?

I'm interested in your ENIG finished boards! I live in the US so we can sort that out in a DM. I'm assuming it's the gold plating that makes the difference? I am waiting for a set of m2 sized screws for assembly so I have time to wait for the next steps. Thanks all for following along and the assistance!

I am waiting for a set of m2 sized screws for assembly so I have time to wait for the next steps. Thanks all for following along and the assistance!