splain

.

- Joined

- Mar 18, 2016

- Messages

- 66

- Likes

- 133

I'm a huge Game Boy nerd but I want an N64 portable, so I want to make one that looks like a huge Game Boy. I think this picture sums it up pretty well:

(I'll probably end up calling it the 64 Boy or something. 64-me-boy??)

I understand this isn't a new idea, but I've been meaning to make an N64 portable for a long time now, and I've always wanted to participate in these Summer contests. So I'm happy to work in the background/shadow of the actual innovators this summer.

I'm still doing a lot of reading and prep-work, basically memorizing this thread: https://bitbuilt.net/forums/index.php?threads/nintendo-game-boy-64-m-boy.4819/

Mine will have a frankencased shell and OEM controls. I have a huge box of cast-off Game Boy shells from a friend, that are ideal for this project since they're scratched and faded. I've built projects that use the upright form factor, with shoulder buttons on the back, and I just don't like how it feels. So I have some big plans for making comfortable shoulder buttons.

If all goes well, I'd also like to 3D-print a shell for an N64 game that looks like a GB game when inserted in this build.

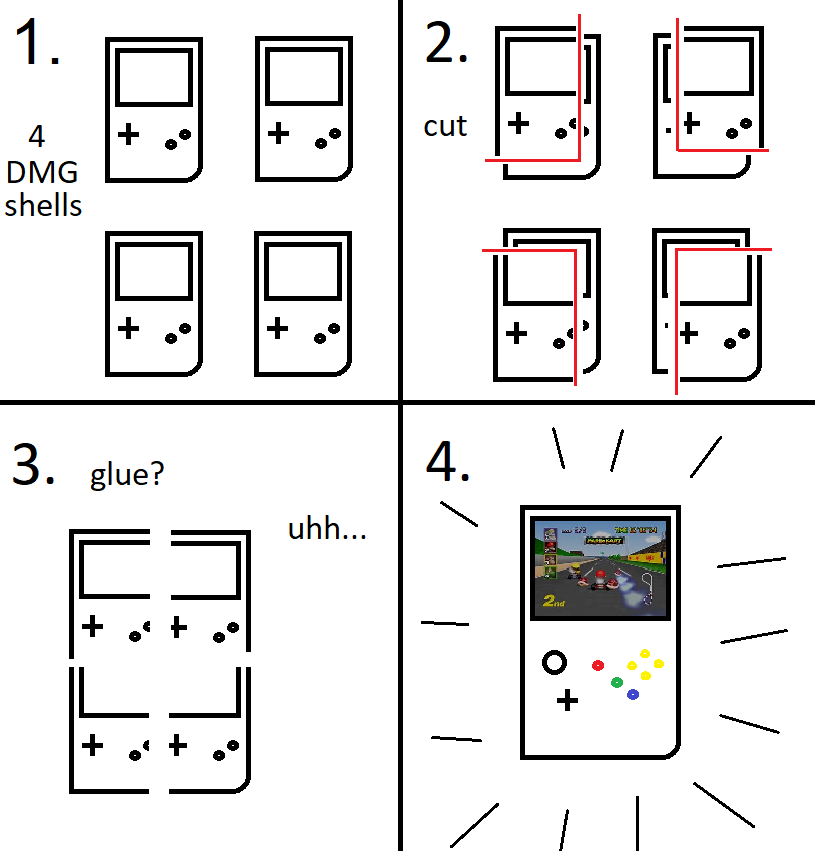

I made this image a while ago but it's still basically the whole plan:

(I'll probably end up calling it the 64 Boy or something. 64-me-boy??)

I understand this isn't a new idea, but I've been meaning to make an N64 portable for a long time now, and I've always wanted to participate in these Summer contests. So I'm happy to work in the background/shadow of the actual innovators this summer.

I'm still doing a lot of reading and prep-work, basically memorizing this thread: https://bitbuilt.net/forums/index.php?threads/nintendo-game-boy-64-m-boy.4819/

Mine will have a frankencased shell and OEM controls. I have a huge box of cast-off Game Boy shells from a friend, that are ideal for this project since they're scratched and faded. I've built projects that use the upright form factor, with shoulder buttons on the back, and I just don't like how it feels. So I have some big plans for making comfortable shoulder buttons.

If all goes well, I'd also like to 3D-print a shell for an N64 game that looks like a GB game when inserted in this build.

I made this image a while ago but it's still basically the whole plan:

. I think also on mine, in the end, OEM buttons would have worked quite well since they will be much better proportioned than the DSL buttons. I was mostly focussed on keeping the design 'thin' and for that, the DSL buttons worked nicely. Also because I cheated there and just did it similarly to how the GBoy did it so I wouldn't have to figure it out myself.

. I think also on mine, in the end, OEM buttons would have worked quite well since they will be much better proportioned than the DSL buttons. I was mostly focussed on keeping the design 'thin' and for that, the DSL buttons worked nicely. Also because I cheated there and just did it similarly to how the GBoy did it so I wouldn't have to figure it out myself.