thedrew

.

- Joined

- Sep 27, 2016

- Messages

- 469

- Likes

- 1,050

So I guess we're all redesigning motherboards now lol.

With the current 3 or so worklogs of reverse engineering of the Wii/PS2 motherboards, I felt inspired. After completing a few portables of my own now, I wanted a challenge for myself to push my growth as a hobbyist. I'm an Eagle user with a hobbyist license (meaning I'm limited to 2 layer designs only), so I'll have to use kicad for this project. I've never worked with kicad, 4 layer board designs, or BGA designs but I'm very familiar with board designs and BGAs in general so shouldn't be too difficult.

Not too much to show as of now, but creating a worklog to hold myself accountable to complete this as well as share the process along the way.

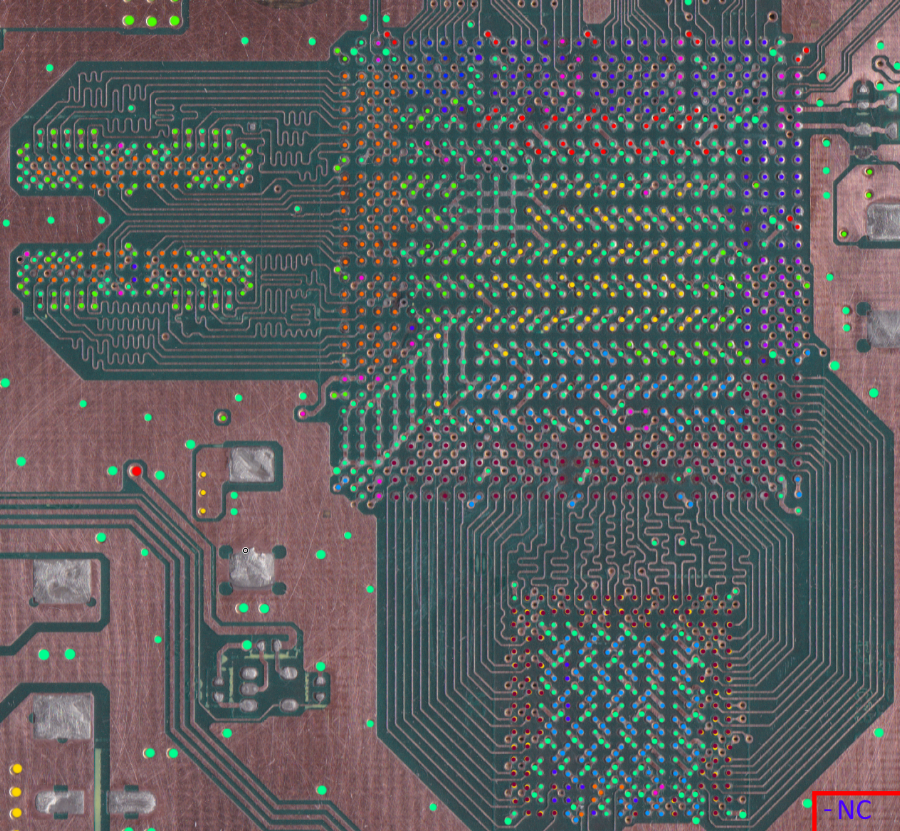

I started off with reviewing the compendium as well as removing the CPU, GPU, and RAM from a 4 layer Wii board I had to confirm various traces under the microscope. I mapped out what every single pad does for all 3 BGAs. Tedious job... over 1200 pads on the motherboard of just those 3 chips.

The compendium was a great start as a lot is already mapped out for you however a lot is also not marked (which didn't need to be marked for the original intent of trimming the board), but I'll need to know what every pad is for my purposes.

I would love for this build to feature an OLED panel, but it's not quite a simple solution.

I experimented with 2 different MIPI AMOLED screens, both slightly disappoint.

1st screen is a 5.5" 1080P panel who's driver board actually accepts 480P natively but looks fuzzy/soft as you would expect a 480P signal to look scaled on a 1080p panel. So I did some research and found the smallest HDMI upscaler money can buy, the Mclassic. The image was only slightly improved but the Mclassic algorithm softens the edges to clean up jagged edges and ultimately it just wasn't a crispy image. This combo was way too expensive for the sub-par image quality, so that option is out.

2nd screen is a 5" odd resolution (960x540, it's a Vita OLED with a MIPI driver) but will not accept any signal less than 720P. So once again forced to hook up the Mclassic to upscale and the image quality is much better than the first due to the driver boards menu options being able to sharpen the image which ended up looking great. But, this is a messy/bulky setup. I thought about reverse engineering the MIPI driver board + the Mclassic into just one board, but is more effort than it's worth with the Mclassic being 6 layers and MIPI board 4 layers... and the slight glitchy-ness from my testing proved this method to be unreliable.

For now, I'm sticking with either 4.3" or 5" IPS 800x480 via HDMI using the gcvideo FPGA (which will most likely be integrated into this board redesign instead of the original AVE). This method is proven to be the most reliable, cleanest, and crispiest video solution currently available. Direct Drive would be nice though...

The regs I will be using are the most efficient I have found that are readily available with efficiency being around 92% under load. I'm using a buck/boost reg for the 3.3v line (to squeeze out a little extra battery life) that automatically switches from a buck reg to a boost when the battery falls below 3.3v.

With the current 3 or so worklogs of reverse engineering of the Wii/PS2 motherboards, I felt inspired. After completing a few portables of my own now, I wanted a challenge for myself to push my growth as a hobbyist. I'm an Eagle user with a hobbyist license (meaning I'm limited to 2 layer designs only), so I'll have to use kicad for this project. I've never worked with kicad, 4 layer board designs, or BGA designs but I'm very familiar with board designs and BGAs in general so shouldn't be too difficult.

Not too much to show as of now, but creating a worklog to hold myself accountable to complete this as well as share the process along the way.

I started off with reviewing the compendium as well as removing the CPU, GPU, and RAM from a 4 layer Wii board I had to confirm various traces under the microscope. I mapped out what every single pad does for all 3 BGAs. Tedious job... over 1200 pads on the motherboard of just those 3 chips.

The compendium was a great start as a lot is already mapped out for you however a lot is also not marked (which didn't need to be marked for the original intent of trimming the board), but I'll need to know what every pad is for my purposes.

I would love for this build to feature an OLED panel, but it's not quite a simple solution.

I experimented with 2 different MIPI AMOLED screens, both slightly disappoint.

1st screen is a 5.5" 1080P panel who's driver board actually accepts 480P natively but looks fuzzy/soft as you would expect a 480P signal to look scaled on a 1080p panel. So I did some research and found the smallest HDMI upscaler money can buy, the Mclassic. The image was only slightly improved but the Mclassic algorithm softens the edges to clean up jagged edges and ultimately it just wasn't a crispy image. This combo was way too expensive for the sub-par image quality, so that option is out.

2nd screen is a 5" odd resolution (960x540, it's a Vita OLED with a MIPI driver) but will not accept any signal less than 720P. So once again forced to hook up the Mclassic to upscale and the image quality is much better than the first due to the driver boards menu options being able to sharpen the image which ended up looking great. But, this is a messy/bulky setup. I thought about reverse engineering the MIPI driver board + the Mclassic into just one board, but is more effort than it's worth with the Mclassic being 6 layers and MIPI board 4 layers... and the slight glitchy-ness from my testing proved this method to be unreliable.

For now, I'm sticking with either 4.3" or 5" IPS 800x480 via HDMI using the gcvideo FPGA (which will most likely be integrated into this board redesign instead of the original AVE). This method is proven to be the most reliable, cleanest, and crispiest video solution currently available. Direct Drive would be nice though...

The regs I will be using are the most efficient I have found that are readily available with efficiency being around 92% under load. I'm using a buck/boost reg for the 3.3v line (to squeeze out a little extra battery life) that automatically switches from a buck reg to a boost when the battery falls below 3.3v.

Last edited: