Thanks for the video, for large heatsinks or where a lot of heat is needed to melt the solder like in the video, it could be a great solution.

I'll certainly try this for other projects, thank you

Let's talk about controllers :

Let's talk about controllers :

At first I was thinking of using a microcontroller-based circuit that emulates a 360 controller so that I could use thinner joysticks and not have to reverse the PCB of an official controller to make custom one.

Unfortunately, I haven't found any projects of this kind.

There's a good reason for this: the 360 and the controller communicate with each other using a security protocol.

I've recently done some research and here are a few project that could make this possible.

I don't understand much about it, but if it helps some people, I'll put it here :

Libxsm3. GP2040-CE. STM32-X360-xinput

1 - Don't do that :

So I chose to reverse an unofficial controller bought on amazon, because its circuit was simpler than an official one.

So I sanded and analysed the circuit, then I made a custom PCB

I broke a pin (because I had stored it with the rest of the other components in a bin).

The controller worked except for 1 button, and even after repair it didn't work.

I hate these crap packages, the pins break all the time and it's super complicated to solder without the pins bridging.

QFN are soooooo much better.

Using an unofficial controller was a huge mistake that made me lose a lot of time, cause I broke the chip and when I bought the same one on Amazon some time later, the chip and the design had changed

Before :________________________After :

2 - It's better :

Before :________________________After :

2 - It's better :

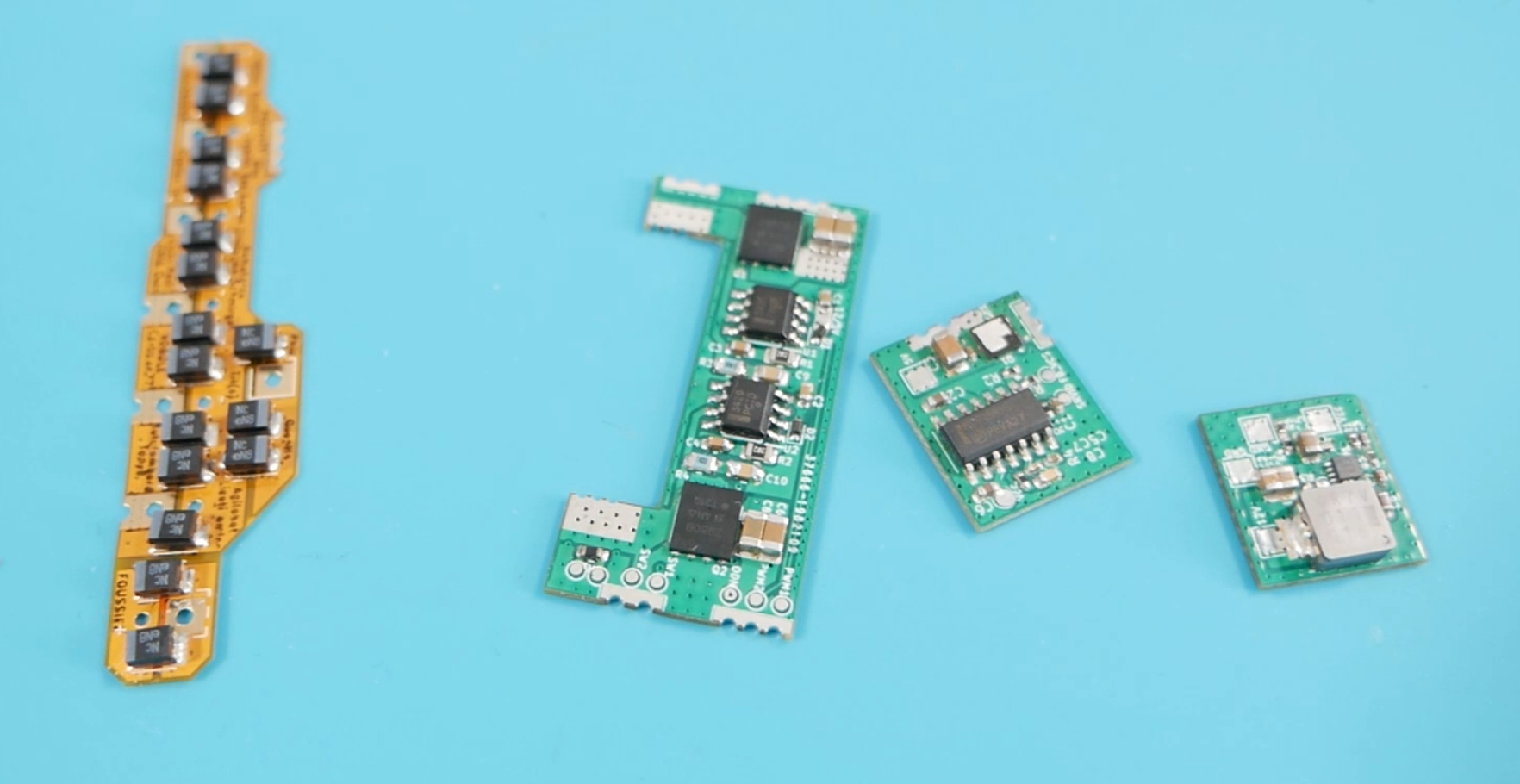

While doing some research, I realized that there were only 2 versions of wired joysticks.

The first are white with grey sticks and the second are black.

The first versions have a large chip, and the second have a small QFN like chip, so I'm obviously going to use the second one.

Early version (white)________________________Smaller chip version (black)

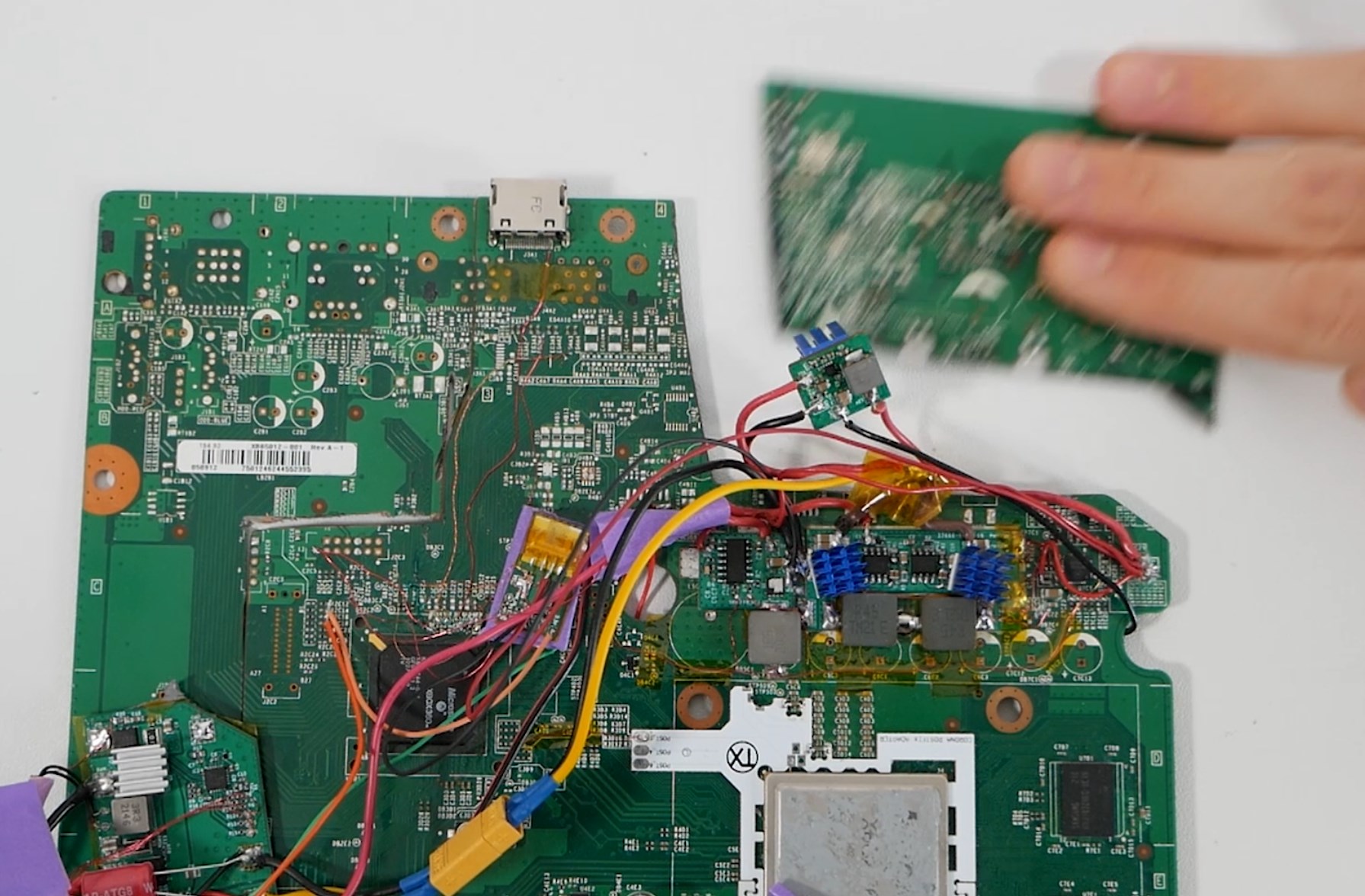

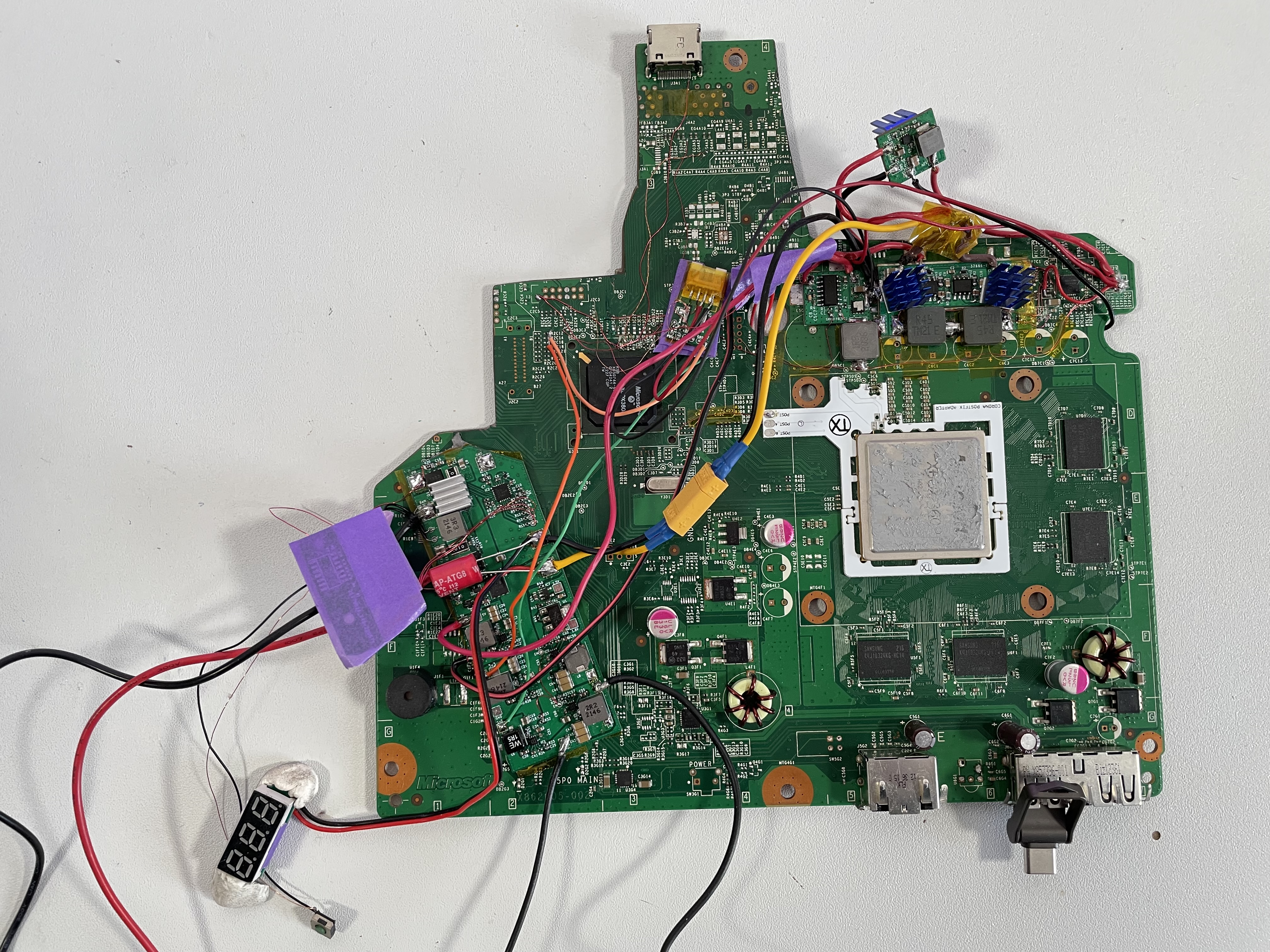

So I reversed the circuit and recreated another custom PCB

This time it was the right one, everything works fine.

With the exception of the Xbox button, it's connected to 1.8V and not to ground, so I modified it on the circuit afterwards.

USB C Power Delivery 20V 5A :

The circuit I was using to have PD 20V 5A is the

CH224K, it's perfect because it requires very few external components.

I made a custom PCB where I integrated it and also added external USB for the console, as well as all screen control buttons.

As there will be external devices connecting to it I added short-circuit protection for 5V and ESD protection for D+-.

The schematic above is up to date, on my PCB you can see a modification because I made a mistake in the first circuit version.

I had ordered the components on HQOnline, but as there were no footprints and I couldn't find them anywhere except on Easy EDA, I had to make my PCB there.

I don't like the software at all, KiCad is much better, but it still saved me time, I'd have been too lazy to recreate the footprints, I hate doing that !

Here are the videos related to this part, I didn't go into detail about the 3D modeling and print testing part because I really don't want to go into it again, so I'll leave that in the videos :

...

...