D_Crepp

.

- Joined

- Oct 14, 2019

- Messages

- 16

- Likes

- 2

As I've posted in a couple of other places, I want to take a shot at building a Wii Micro. This build is inspired by @Gman and @jefflongo . Gman for coming up with the concept and perfecting it through his permutations of the Wii micro over time. Then Jeff's worklog broke down really well how to approach assembling the boards and setting a standard of laying all the components down in the case.

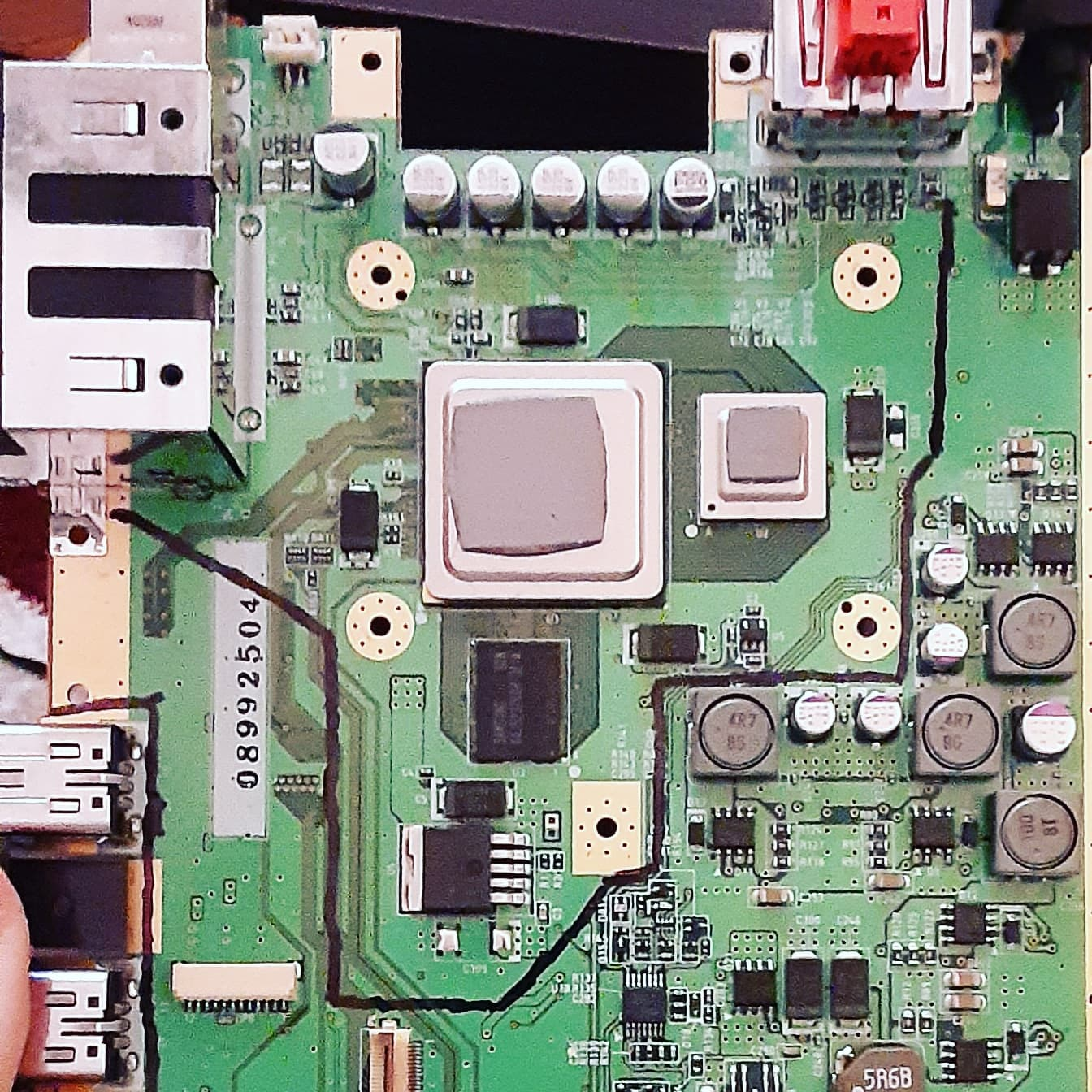

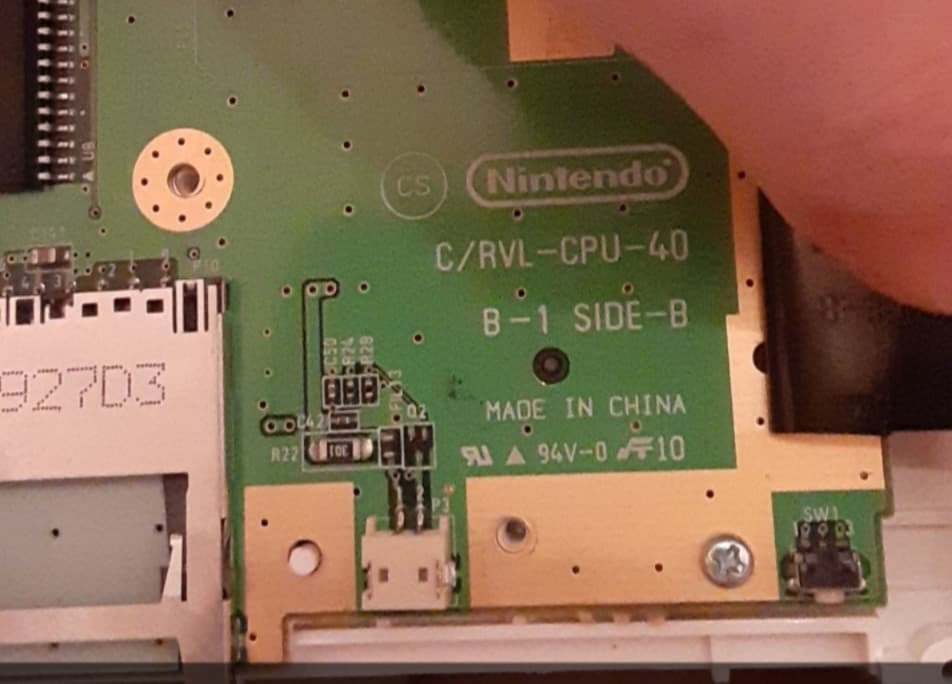

If I should I succeed, I will more likely build a portable later on. The board I will be using came from a white Wii console; counter-intuitively, the revision number on the board tells me it is a 4 layer board. (Images below) After some tweaking in MMM and a PortablizeMii install, this board runs Wii games fairly well enough for me to not need to buy another console. The features I would like my Wii Micro to have go as follows:

-GC Controller Ports and USB Ports (Obviously)

-Bluetooth Module and Sensor Bar compatibility

-Power and Sync buttons via hard tact switches or similar

-USB type C for power port

-Power Mii Regulator board...maybe? Please?

-40x40x10mm exhaust fan (possibly Noctua, space permitting)

I've read that original sensor bars need 12v for power but some of the newer ones can run off of just 5v? Or I'll more than likely resort to building my own sensor bar...

I have not relocated my U10 yet, because I'd like to know thoughts of people from this community who have experience as well as tips for soldering together small components/wires. Working with electronics is kind of a weakness for me at the moment, that's why I wanted to take a slightly smaller step into console modding rather than attempting a portable right away. Links to guides, comments, tips, anything helpful is appreciated in advance.

If I should I succeed, I will more likely build a portable later on. The board I will be using came from a white Wii console; counter-intuitively, the revision number on the board tells me it is a 4 layer board. (Images below) After some tweaking in MMM and a PortablizeMii install, this board runs Wii games fairly well enough for me to not need to buy another console. The features I would like my Wii Micro to have go as follows:

-GC Controller Ports and USB Ports (Obviously)

-Bluetooth Module and Sensor Bar compatibility

-Power and Sync buttons via hard tact switches or similar

-USB type C for power port

-Power Mii Regulator board...maybe? Please?

-40x40x10mm exhaust fan (possibly Noctua, space permitting)

I've read that original sensor bars need 12v for power but some of the newer ones can run off of just 5v? Or I'll more than likely resort to building my own sensor bar...

I have not relocated my U10 yet, because I'd like to know thoughts of people from this community who have experience as well as tips for soldering together small components/wires. Working with electronics is kind of a weakness for me at the moment, that's why I wanted to take a slightly smaller step into console modding rather than attempting a portable right away. Links to guides, comments, tips, anything helpful is appreciated in advance.

Attachments

-

1 MB Views: 220