Orako

.

- Joined

- Mar 30, 2022

- Messages

- 3

- Likes

- 5

6/13/22 - Finally started work on my first portable the other day, and man was it fun. I got so wrapped up I almost forgot to write a worklog, so this is going to be a lot of stuff on the first post.

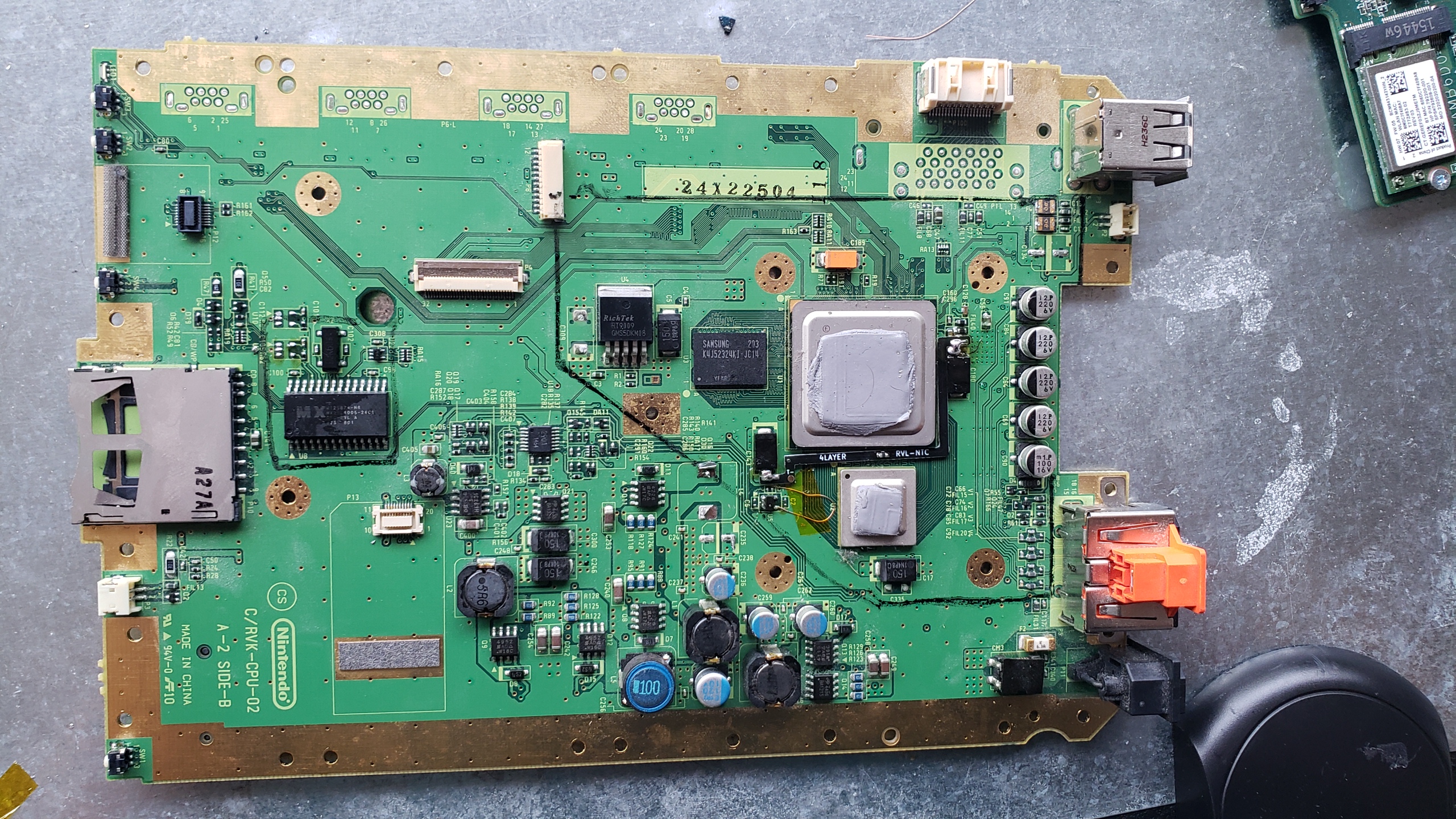

First things first, the prep. I purchased a black Wii off of Ebay for around $30 usd total. It turned out to be an RVK-CPU-02, neato. All my orders are currently in except for an Ashida case since I'm still waiting on a reply from the guy I'm ordering from. I don't have a printer, so I went with the cheapest option I could find and it took some digging but I found a service off of Etsy with plenty of positive feedback singing praises, who claimed to quite literally beat 3d printing service prices by 50%. We'll have to see how that goes. Any tips on info to provide him to ensure a successful print would be nice. I'm planning either black ABS or clear resin if it's not too expensive (long shot I know). Otherwise, my first digikey order, my 4layer order, and my amazon orders have all arrived. I'm waiting on backordered speakers from digikey and the variable resistor from mouser which should arrive tomorrow.

For this build I'm going to be following the Ashida build to a T with a couple exceptions. I would like to have the mx chip and the bluetooth module since I'm planning to make this a gc/wii portable. I'm comfortable using a wireless sensor bar or even the double candle trick if I need to. I don't currently plan on modifying the Ashida's case in any way, but in a future project I may try to add gamecube ports and/or an HDMI out. Finally, since it was sold out at the time, I'm using a pms-lite instead of a pms-2 so we'll have to do a little more work with the 1.8v line.

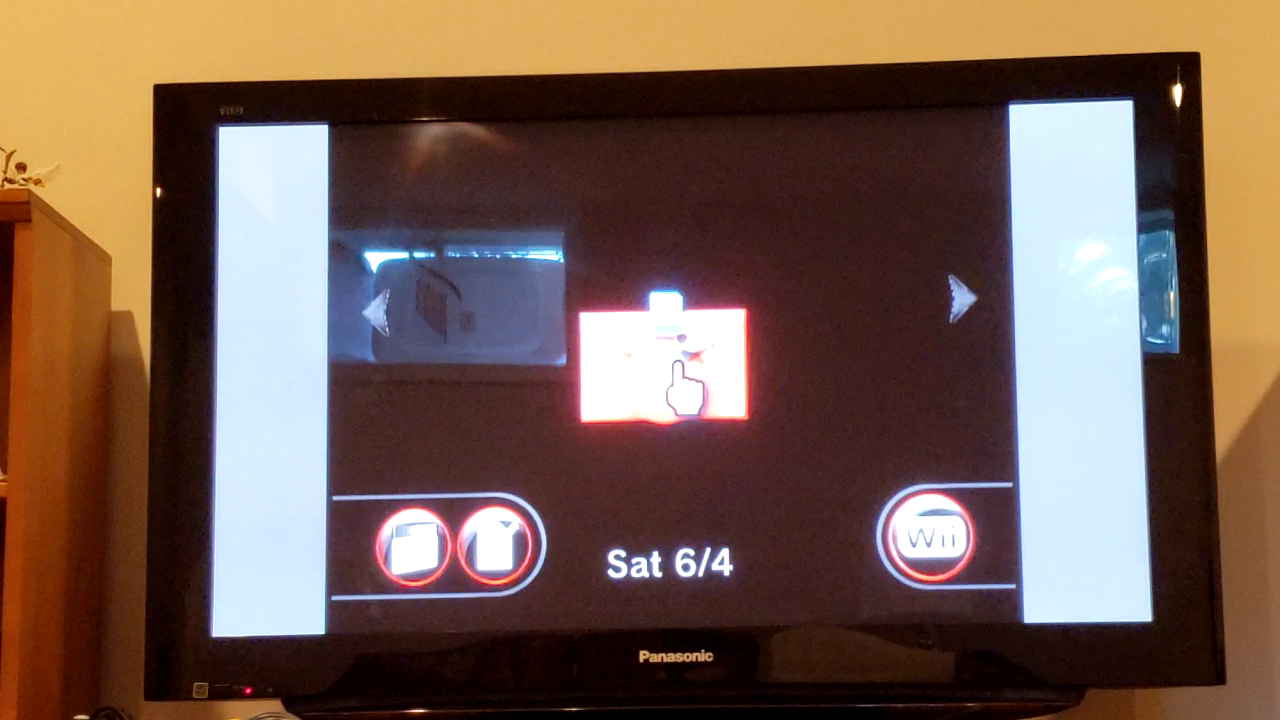

Aaaaaand we're off! I started by softmodding the Wii. This happens to also be my first experience with any homebrew as well. The Wii I purchased happened to come with the Homebrew channel preinstalled, but for the authentic experience I wiped the console and reinstalled it myself.

(Apologies for the blurry photos. I'm planning on editing this all into a video at the end and I realized literally today that my phone was recording in 720p30. Quality should greatly improve in the coming edits/replies)

Got letterbomb working pretty easily, installed the Homebrew channel and later went back and installed Bootmii and made a backup. Not much to really say here, it's a straightforward process if you follow the guides.

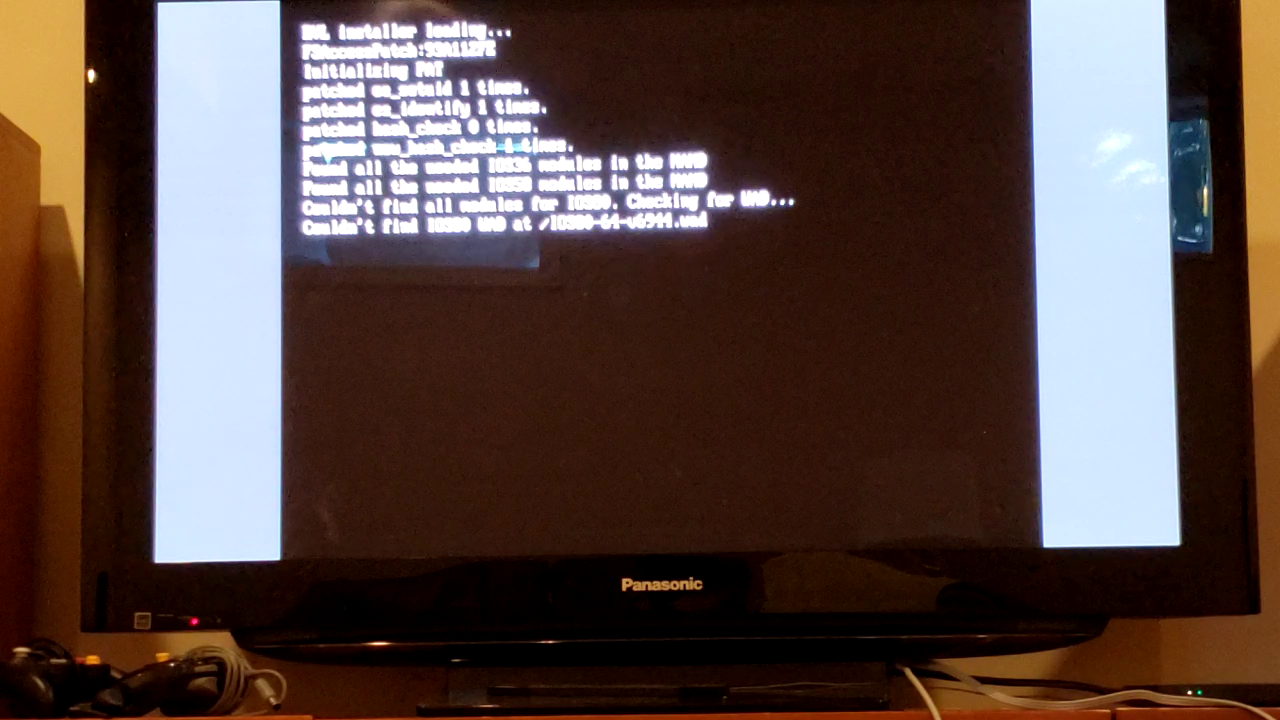

RVLoader was a bit more of an involved process. I didn't even know about the WADs the first couple times I tried to install it.

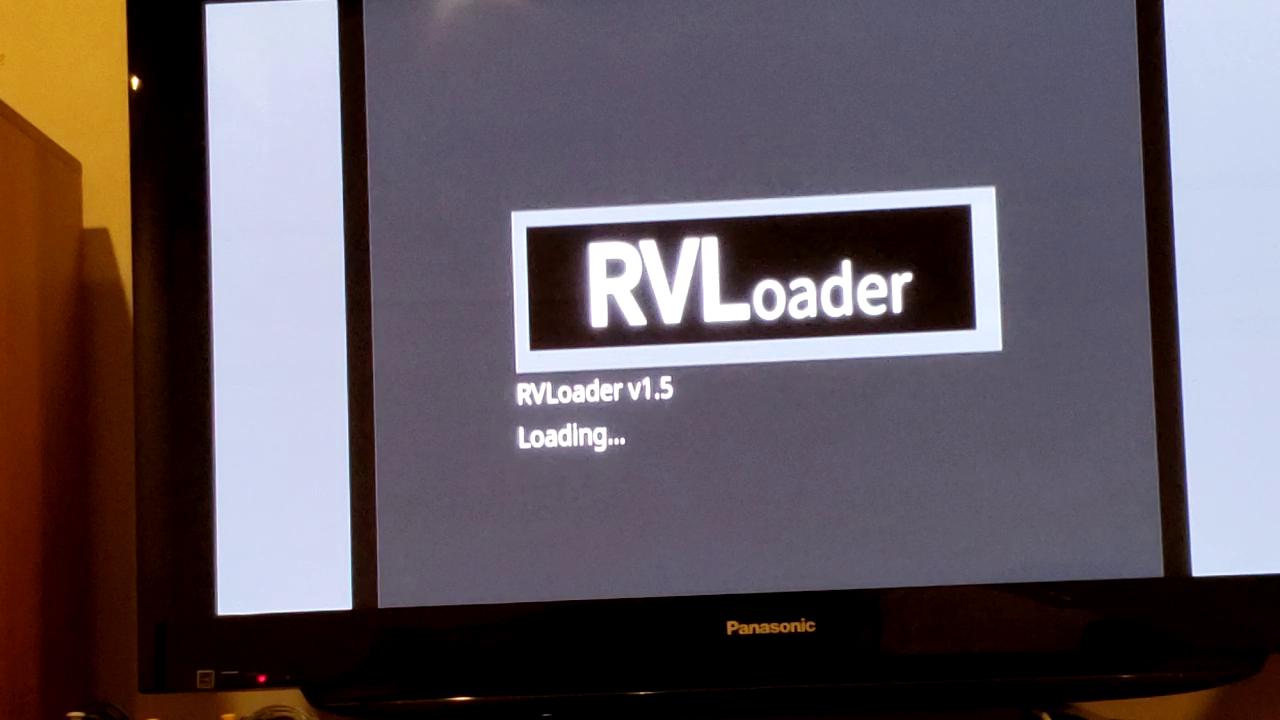

Eventually got it though, so that's cool. Patched out WiFi, patched in VGA, and all games worked well. Even played through a bit of Super Paper Mario while I was waiting to trim.

Now begins the hard part. A bricked Wii is maybe recoverable. A shorted or improperly cut Wii is rarely recoverable. I think, anyways, it's still my first time. Anyways, trimming the Wii was daunting but i could always cut far outside the lines. What really freaked me out was the u10 relocation. After I opened up the Wii and saw just how small the solder joints were, it definitely made me a little nervous. You know what that means: practice board time.

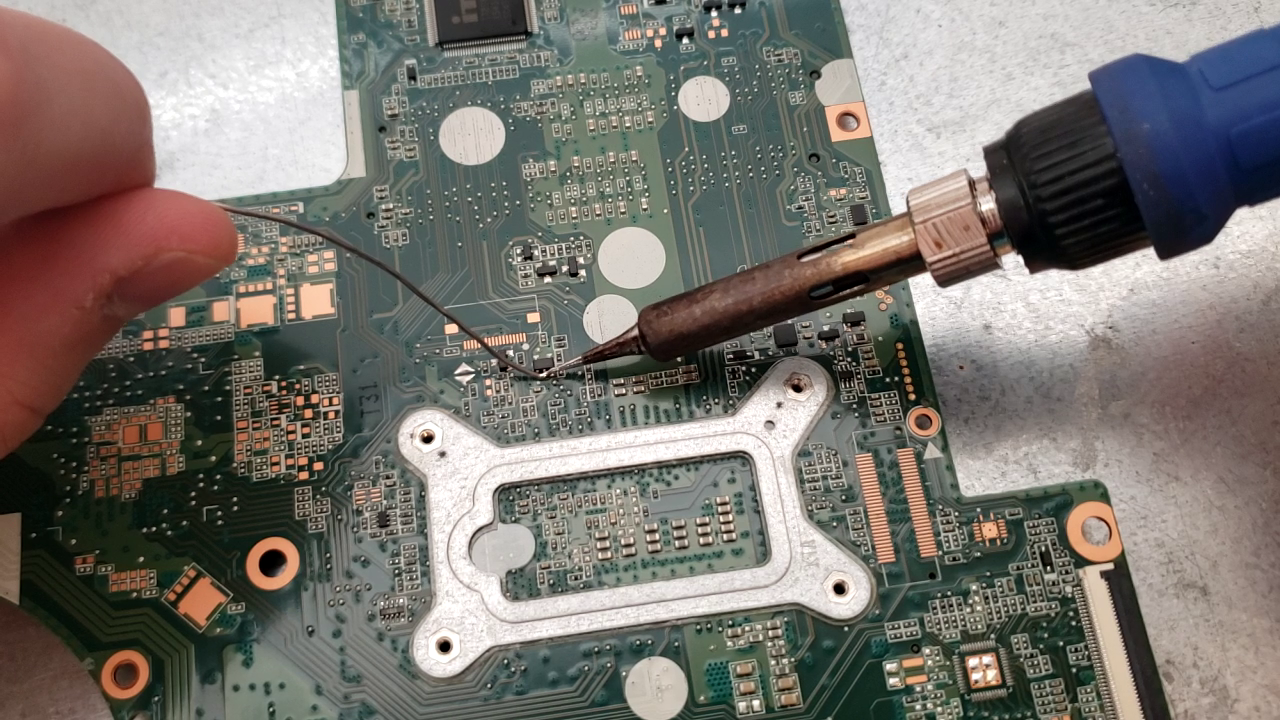

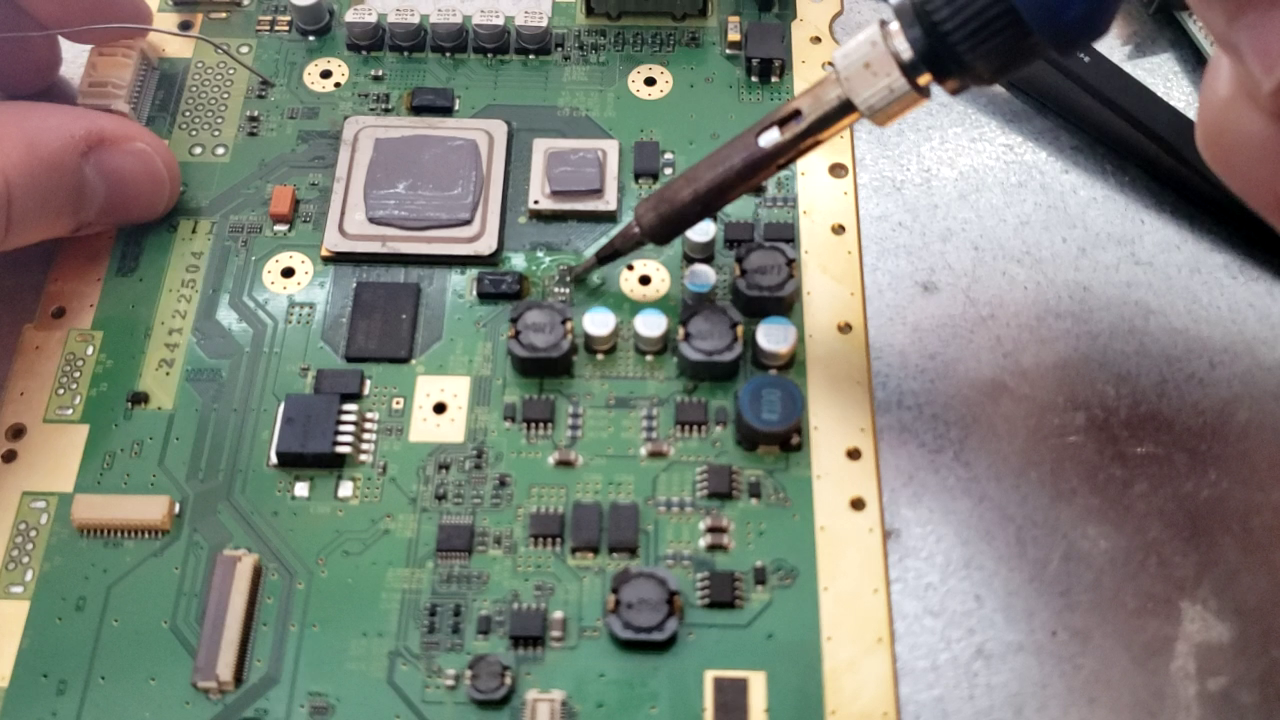

I really like taking things apart, so I happened to have an old laptop mobo on hand. I found a component that looked like u10, with three legs on one side and two on the other, and practiced the blob method there as I didn't have a hot air station. I tried to use a heat gun until people told me not to... and the cheap $30 Amazon junk one I bought started smoking. Yikes. When I felt I had the technique down I moved on to u10 and u9. I started with trying to remove those since if I burned up the traces on one, I could retry on the other, whereas burning the traces on u5 would be mostly unsalvageable for my skill set. With my iron set at 500f, I attempted my first micro-soldering experience that really mattered.

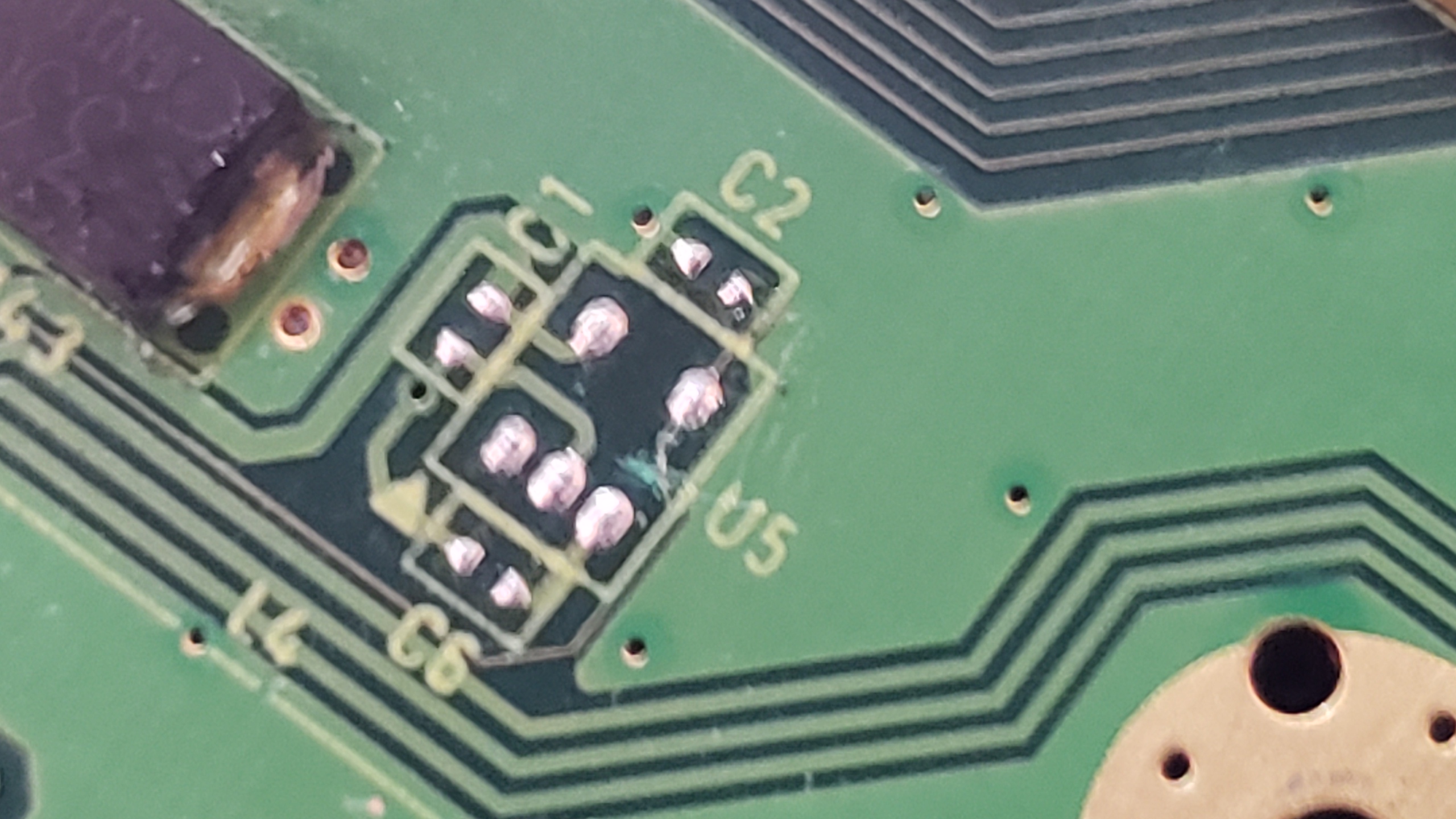

It's unfocused as heck, but I got it! After fiddling with u9 until I was worried I would burn the traces off, I tried again with u10 and managed to get it pretty easily. Quite the rush of adrenaline when it finally starts sliding around, though I did pry it a little with my tweezers. Thankfully I didn't tear any traces up. Next up was the relocation.

u5 actually came off way easier than u10 or u9, no prying needed. Guess I started to really get the technique down. I removed the surrounding capacitors, cut the trace and moved on to soldering.

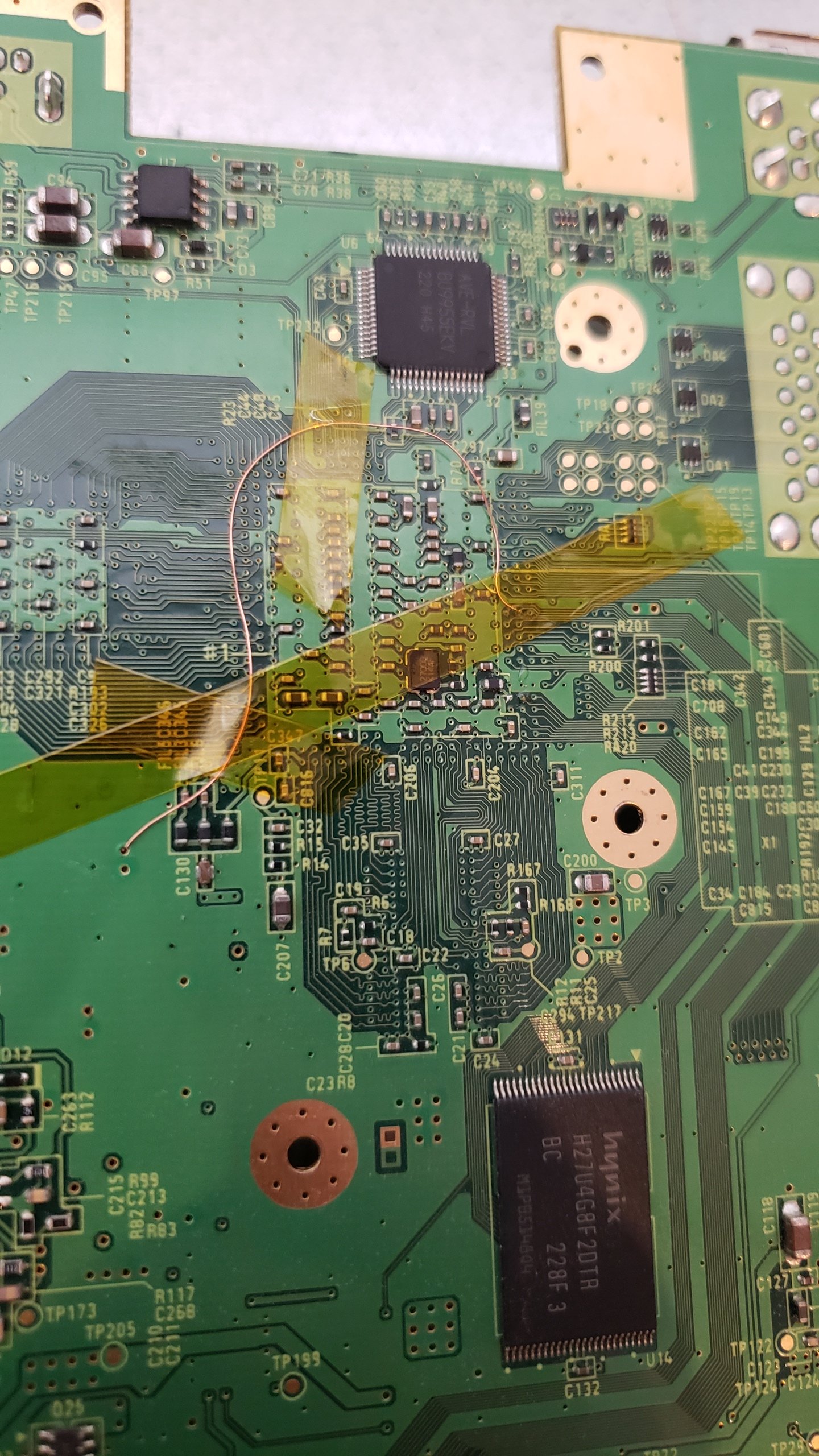

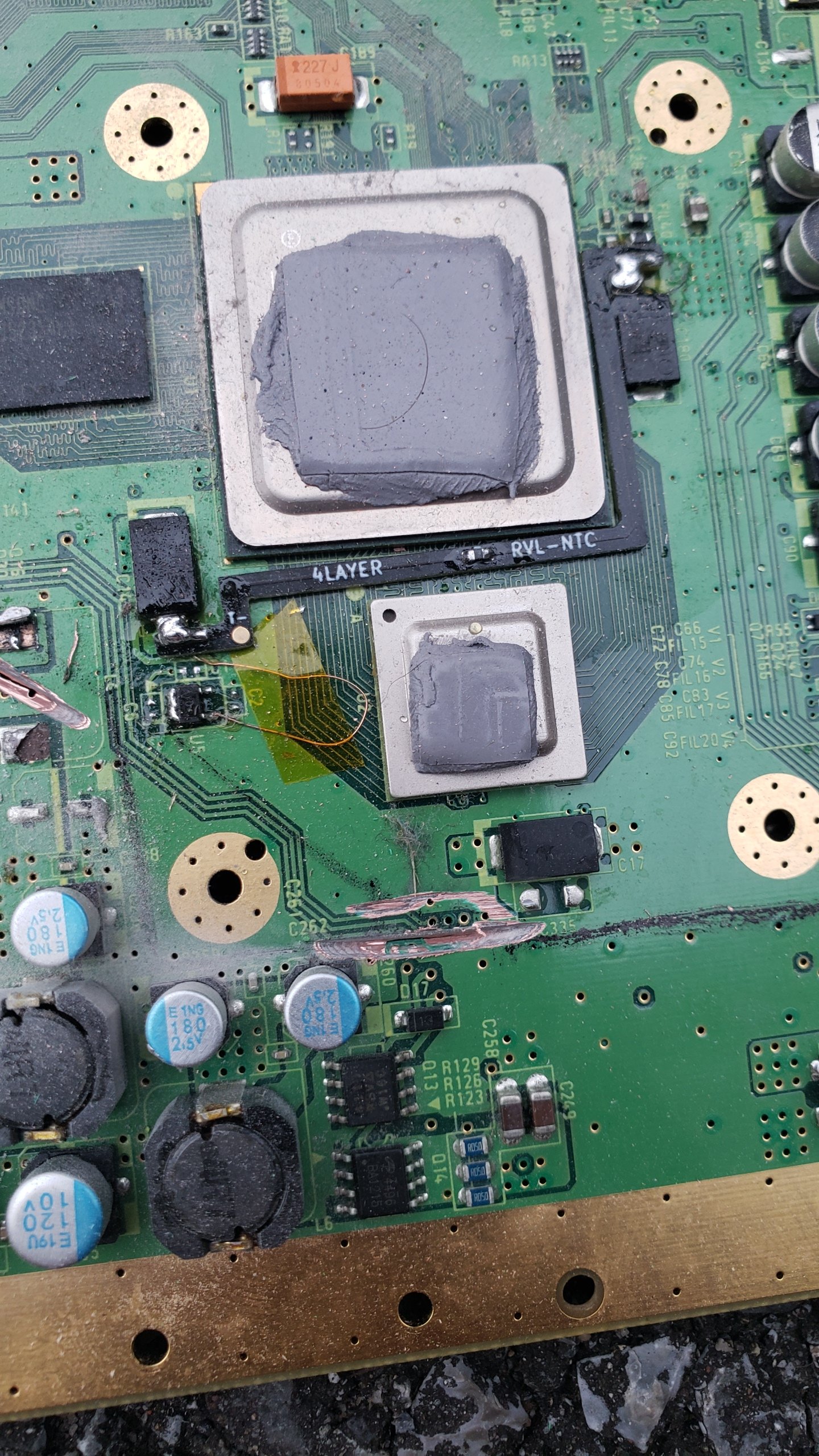

It went really well! Using some flux as adhesive, I aligned the u10 under a cheap digital microscope I bought and began soldering. The burnt-looking stuff next to u10 is just flux, I actually haven't burnt anything on the board yet which is really cool to see. The one ripped trace underneath is from when I was removing components for the trim, I didn't really care since that trace is getting trimmed off anyways. Next up we have the jumper wire.

Honestly? The hardest part was keeping track of the via on the back. I had a little mishap where I didn't realize the via had solder mask on it, but under that microscope scratching it off and looking for the gold was quite easy. Really proud of myself so far. All that's left before the trim was to hook up the RVL-NTC.

Still alright, but it couldn't be perfect forever. When I eventually attempt this again, I see myself trying to find a different via to thread the u10 jumper through. As it stands the RVL-NTC covers the hole the jumper threads through, meaning if the u10 relo was a failure, which I can't check since I had already removed components for the trim, then I'll have to undo the NTC as well. This also meant the solder for the NTC came dangerously close to the via it was threaded through. Definitely all good notes to take for future projects. Otherwise, actually soldering on the NTC was tougher than the other joints, believe it or not. Maybe I wasn't using enough flux, but no matter what I tried the solder only seemed to blob up on the NTC, not on the capacitor. Eventually I got it and confirmed continuity, so I'm satisfied even if the joints aren't that great.

Which just leaves trimming.

Here's the trim line.

Slipped with the dremel, but I was told the board wasn't dead so I kept going.

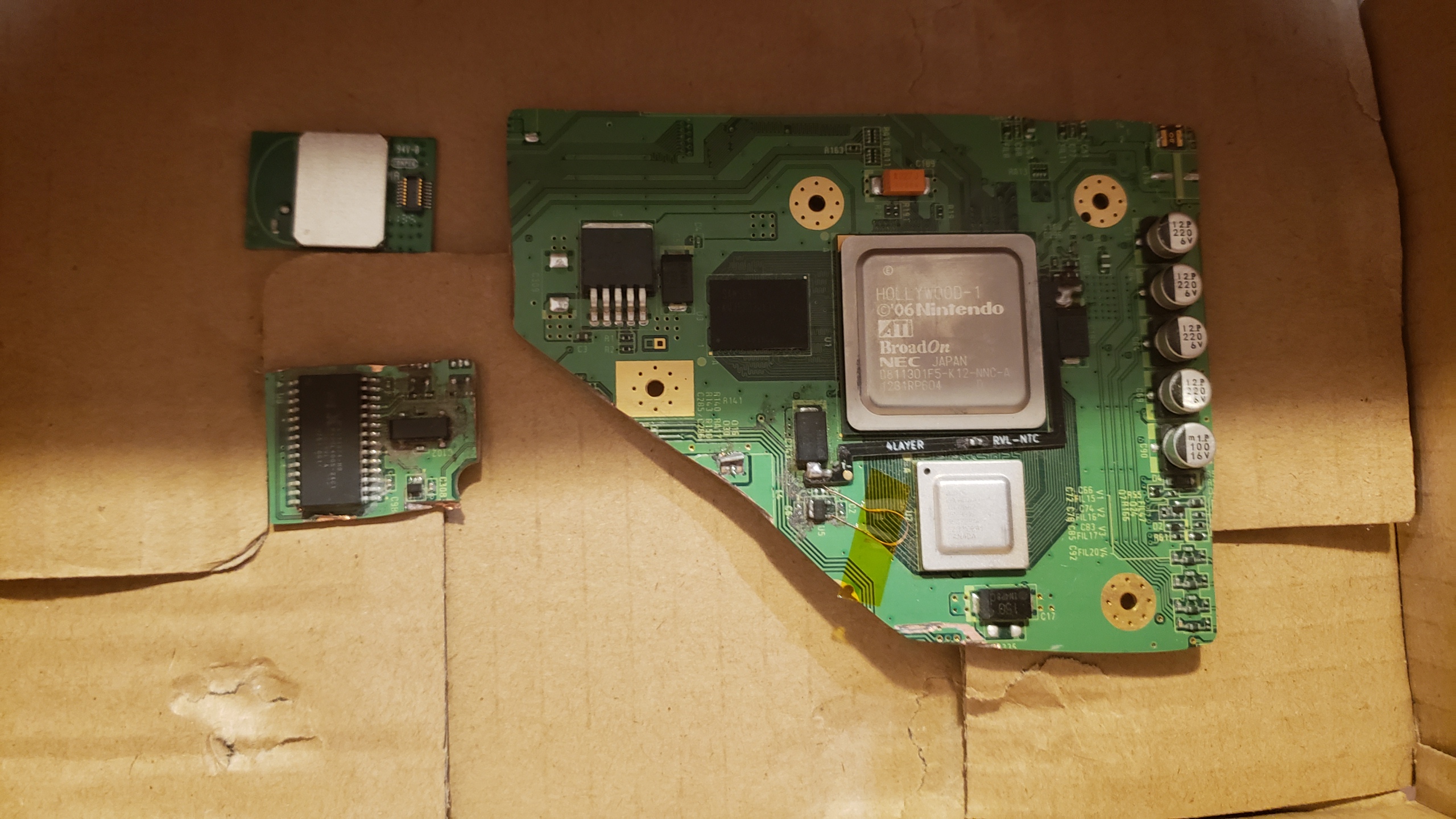

Here's the rough board trim. It was around here I was told to cover the chips with masking tape to prevent dust getting under and causing shorts.

Here's the final, sanded, and cleaned trim. Initially wanted to keep that fifth screw hole, but eventually just decided to take it off to minimize the number of gouges I had in the board. All that's left now is to test resistances. My final resistances were:

com/+

gnd/1v: 60.1Ω

gnd/1.15v: 29.4Ω

gnd/1.8v: 36.7Ω

gnd/3v3: 6.03-6.14kΩ depending on gnd plane

1v/1.15v: 110Ω

1v/1.8v: 117Ω

1v/3v3: 6.36kΩ

1.15v/1.8v: 94.3Ω

1.15v/3v3: 6.16kΩ

1.8v/3v3: 6.19kΩ

They seem a little low compared to the other RVK-CPU-02 measurements I've seen so if anyone thinks this board is dead let me know!

That's about all I have for now. Excited for the rest even if I have to redo the trim. Can't wait to see the finished product.

First things first, the prep. I purchased a black Wii off of Ebay for around $30 usd total. It turned out to be an RVK-CPU-02, neato. All my orders are currently in except for an Ashida case since I'm still waiting on a reply from the guy I'm ordering from. I don't have a printer, so I went with the cheapest option I could find and it took some digging but I found a service off of Etsy with plenty of positive feedback singing praises, who claimed to quite literally beat 3d printing service prices by 50%. We'll have to see how that goes. Any tips on info to provide him to ensure a successful print would be nice. I'm planning either black ABS or clear resin if it's not too expensive (long shot I know). Otherwise, my first digikey order, my 4layer order, and my amazon orders have all arrived. I'm waiting on backordered speakers from digikey and the variable resistor from mouser which should arrive tomorrow.

For this build I'm going to be following the Ashida build to a T with a couple exceptions. I would like to have the mx chip and the bluetooth module since I'm planning to make this a gc/wii portable. I'm comfortable using a wireless sensor bar or even the double candle trick if I need to. I don't currently plan on modifying the Ashida's case in any way, but in a future project I may try to add gamecube ports and/or an HDMI out. Finally, since it was sold out at the time, I'm using a pms-lite instead of a pms-2 so we'll have to do a little more work with the 1.8v line.

Aaaaaand we're off! I started by softmodding the Wii. This happens to also be my first experience with any homebrew as well. The Wii I purchased happened to come with the Homebrew channel preinstalled, but for the authentic experience I wiped the console and reinstalled it myself.

(Apologies for the blurry photos. I'm planning on editing this all into a video at the end and I realized literally today that my phone was recording in 720p30. Quality should greatly improve in the coming edits/replies)

Got letterbomb working pretty easily, installed the Homebrew channel and later went back and installed Bootmii and made a backup. Not much to really say here, it's a straightforward process if you follow the guides.

RVLoader was a bit more of an involved process. I didn't even know about the WADs the first couple times I tried to install it.

Eventually got it though, so that's cool. Patched out WiFi, patched in VGA, and all games worked well. Even played through a bit of Super Paper Mario while I was waiting to trim.

Now begins the hard part. A bricked Wii is maybe recoverable. A shorted or improperly cut Wii is rarely recoverable. I think, anyways, it's still my first time. Anyways, trimming the Wii was daunting but i could always cut far outside the lines. What really freaked me out was the u10 relocation. After I opened up the Wii and saw just how small the solder joints were, it definitely made me a little nervous. You know what that means: practice board time.

I really like taking things apart, so I happened to have an old laptop mobo on hand. I found a component that looked like u10, with three legs on one side and two on the other, and practiced the blob method there as I didn't have a hot air station. I tried to use a heat gun until people told me not to... and the cheap $30 Amazon junk one I bought started smoking. Yikes. When I felt I had the technique down I moved on to u10 and u9. I started with trying to remove those since if I burned up the traces on one, I could retry on the other, whereas burning the traces on u5 would be mostly unsalvageable for my skill set. With my iron set at 500f, I attempted my first micro-soldering experience that really mattered.

It's unfocused as heck, but I got it! After fiddling with u9 until I was worried I would burn the traces off, I tried again with u10 and managed to get it pretty easily. Quite the rush of adrenaline when it finally starts sliding around, though I did pry it a little with my tweezers. Thankfully I didn't tear any traces up. Next up was the relocation.

u5 actually came off way easier than u10 or u9, no prying needed. Guess I started to really get the technique down. I removed the surrounding capacitors, cut the trace and moved on to soldering.

It went really well! Using some flux as adhesive, I aligned the u10 under a cheap digital microscope I bought and began soldering. The burnt-looking stuff next to u10 is just flux, I actually haven't burnt anything on the board yet which is really cool to see. The one ripped trace underneath is from when I was removing components for the trim, I didn't really care since that trace is getting trimmed off anyways. Next up we have the jumper wire.

Honestly? The hardest part was keeping track of the via on the back. I had a little mishap where I didn't realize the via had solder mask on it, but under that microscope scratching it off and looking for the gold was quite easy. Really proud of myself so far. All that's left before the trim was to hook up the RVL-NTC.

Still alright, but it couldn't be perfect forever. When I eventually attempt this again, I see myself trying to find a different via to thread the u10 jumper through. As it stands the RVL-NTC covers the hole the jumper threads through, meaning if the u10 relo was a failure, which I can't check since I had already removed components for the trim, then I'll have to undo the NTC as well. This also meant the solder for the NTC came dangerously close to the via it was threaded through. Definitely all good notes to take for future projects. Otherwise, actually soldering on the NTC was tougher than the other joints, believe it or not. Maybe I wasn't using enough flux, but no matter what I tried the solder only seemed to blob up on the NTC, not on the capacitor. Eventually I got it and confirmed continuity, so I'm satisfied even if the joints aren't that great.

Which just leaves trimming.

Here's the trim line.

Slipped with the dremel, but I was told the board wasn't dead so I kept going.

Here's the rough board trim. It was around here I was told to cover the chips with masking tape to prevent dust getting under and causing shorts.

Here's the final, sanded, and cleaned trim. Initially wanted to keep that fifth screw hole, but eventually just decided to take it off to minimize the number of gouges I had in the board. All that's left now is to test resistances. My final resistances were:

com/+

gnd/1v: 60.1Ω

gnd/1.15v: 29.4Ω

gnd/1.8v: 36.7Ω

gnd/3v3: 6.03-6.14kΩ depending on gnd plane

1v/1.15v: 110Ω

1v/1.8v: 117Ω

1v/3v3: 6.36kΩ

1.15v/1.8v: 94.3Ω

1.15v/3v3: 6.16kΩ

1.8v/3v3: 6.19kΩ

They seem a little low compared to the other RVK-CPU-02 measurements I've seen so if anyone thinks this board is dead let me know!

That's about all I have for now. Excited for the rest even if I have to redo the trim. Can't wait to see the finished product.

Attachments

-

1.3 MB Views: 78

-

345.8 KB Views: 82

-

531.1 KB Views: 80

Last edited: